What is needed to lay tiles on the floor. Laying tiles on the floor yourself. Creating a new screed

Laying tiles on the floor with your own hands is a very labor-intensive process that requires a certain amount of care. If you follow all the rules and technologies, you will be able to obtain a reliable and durable floor covering. It should also be taken into account that self-made repairs can significantly save the family budget.

The work ahead will be long, it will be divided into several stages, which are completely interconnected.

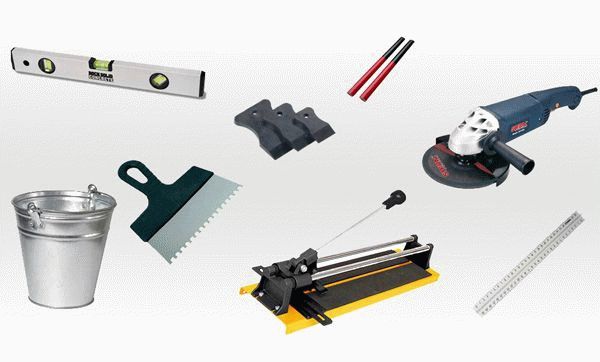

Tool

First of all, the necessary tool is determined. You will need:

- Hammer and rubber mallet.

- Chisel.

- A set of simple spatulas, as well as a serrated one.

- Trowel.

- Level and roulette.

- Tile cutter.

- Tile adhesive, grout and sealant.

- A set of crosses for creating even seams.

- Container for water and solution.

Of course, depending on the specific situation, other devices may be needed.

Calculation of material quantity

It is better to do this at the initial stage. Many people think that calculating floor tiles is quite difficult, but in reality everything is different. This is done according to the following principle:

The first step in installing tiles is calculating the number of tiles, so it is important to carry out this task correctly

The first step in installing tiles is calculating the number of tiles, so it is important to carry out this task correctly - Define object parameters. Its width and length. The total area is calculated.

- The resulting indicator is divided by the area of the selected tile (several options can be calculated at once).

- Ten percent is added to the resulting amount. This will be the necessary supply.

For example, the floor has a size of 3*3 meters. This means the area will be nine square meters. An ordinary tile has a size of 30*30 cm. The resulting tile area is converted into meters: 0.09 sq. m. Total: 9:0.09+10%=110 pieces. When calculating trimming, the size of the seams is also taken into account.

On a note! Any large hardware store that sells tiles offers free services for calculating the required number of products.

Working with the surface

Laying floor tiles is only possible on a well-prepared surface. First, everything unnecessary is removed from the room. The old floor covering is removed. Communication is checked. This is precisely what is worth focusing on. The fact is that all water supply and drainage connections are done in advance. You should not work on the floor until all problems in this area have been resolved. If possible, it is advisable to immediately hide the pipes.

When all technical procedures are completed, the surface leveling process begins. It is much easier to carry out work when it comes to new houses and apartments that only have screed and plaster. In old premises - you will have to try. The fact is that objects built many years ago may have different foundations. Sometimes you will have to create a new surface.

On a note! When it comes to bathrooms located in old apartment buildings, people pay attention to the baseboards. They are made from a durable cement mixture. They will have to be removed completely, along with the coating.

Preparing the floor before laying tiles

- After cleaning, there is a lot of dust and dirt left that needs to be removed. Floor tiles do not tolerate anything unnecessary.

- The surface is measured. This is done to determine the existing curvature. Small differences are allowed - no more than 5 mm per 2 meters. Any defects that exceed the specified parameters require a more serious approach.

- A leveling mixture will help correct the situation. It is better to choose cement-sand compositions. This mixture is poured along the installed beacons. The result is an even and smooth base. But this procedure is carried out after all deep cracks and potholes have been sealed.

- Wood floors need the same treatment. The only thing is that the procedure will be slightly different. First, the reliability of the joists and boards is checked. Next, the wood is impregnated with oil paints. The cracks are sealed in advance with elastic putty. A layer of waterproofing will be laid on the dried surface. A reinforcing mesh is pulled on top. The prepared mixture is poured.

- Don’t forget about priming with penetrating compounds.

Priming the floor before laying the tiles ensures a stronger connection of the tiles to the floor surface

Priming the floor before laying the tiles ensures a stronger connection of the tiles to the floor surface On a note! Rooms with high humidity require more careful treatment. A prerequisite will be -. Different materials can be used for this. Some can be laid (film, roll), others can be applied using a roller and brush (liquid).

Indeed, laying floor tiles with your own hands requires a balanced approach to the surface. Small imperfections cannot be expected to be corrected by the final coating.

Marking

There are two main ways of tiling a floor. Each has its own characteristics.

- The simplest option is to start installation from the far corner. The movement is towards the doorway. This method is suitable for small objects, as well as for rooms with complex geometry. Ideal for those who do not have sufficient experience.

- A more complex option can also be used. In this case, veneering begins from the middle. The surface is pre-marked - you need to get four identical squares or rectangles. The lines will run through the center, creating four corners. You should choose one, it will serve as a starting point for work. Material laid according to this principle will require trimming along the entire perimeter. Therefore, such manipulations are carried out with sufficient experience.

It is recommended to start work with a preliminary arrangement of elements. That is, laying tiles on the floor is done “dry”. This will help you calculate everything correctly right away. Especially if there is a pattern that requires adjustment. It is also important to take into account the presence of seams. This method allows you to once again evaluate the size of the trim and, if necessary, make adjustments.

Advice! When making initial calculations, pay attention to the areas that will be located along the walls. To get a beautiful floor surface, you should be guided by the principle that the tiles should not be cut into narrow strips. The size should be more than 35-40% of the total width.

Laying

Laying ceramic tiles on the floor begins with preparing the adhesive. Even if you purchased a ready-made composition, it needs to be stirred thoroughly. When using a dry mixture, you need to follow the recommendations provided by the manufacturer.

You shouldn’t immediately prepare a large supply of glue. It should be taken into account that the process may take a significant amount of time. Then the composition will begin to lose its properties. It will simply freeze.

The work is carried out according to the following principle:

On a note! The space near the walls begins to be sealed at the last stage. This approach will help reduce time, since in this case it will be possible to trim all the material at once.

- It should be taken into account that the technology of laying tiles on the floor does not allow the presence of voids. If such a defect is allowed to form, there is a high probability of damage to the coating.

- Immediately wipe off excess glue from the surface. Otherwise, the glue will have to be removed with a special scraper.

- The question often arises: how long does it take for the laid material to dry? It depends on the mixture used, but it is not recommended to walk on the floor for two days.

- At the last stage, rubbing of the seams is used. This procedure allows you to get beautiful gaps. When the need arises, additional sealant is used.

If you analyze all the requirements and rules, it will become clear that laying tiles on the floor is a difficult task, but doable.

Ceramic tile flooring is quite popular. This material is often used to decorate floors in the bathroom, toilet or other utility rooms (for example, a boiler room). Laying floor tiles with your own hands is a rather labor-intensive process. It requires care and accuracy. And we will tell you how this is done in this article.

Preparatory work

Ceramic tile laying work requires preparation. The first thing you need to do is stock up on the necessary tools. You will need:

- trowel, notched and wide spatula;

- building level and ruler;

- marker or pencil;

- tile cutter;

- hammer (simple and rubber), pliers, drill or hammer drill;

- plastic crosses for aligning seams;

- primer, grout, adhesive;

- ceramic tile.

To calculate the required number of tiles, you should resort to simple mathematics. Knowing the area of the room, divide it by the area of one tile. In this case, it is worth taking into account the width of the seams, 2–5 mm. As a result, you will receive the required amount of material. Add 10-15% to this value. This reserve is necessary; the tile may crack during operation, or you may cut a piece incorrectly.

It is imperative to make a reserve. The fact is that the shades of tiles can vary even in the same batch. Therefore, if you are missing just one square, it will be very difficult to find the right color.

Now you need to prepare the surface. Remove all items from the room (furniture, plumbing fixtures, etc.). If there were old tiles on the floor, you need to get rid of them. You also need to do the same with the old adhesive mass. A hammer drill with a special attachment in the form of a spatula or a chisel with a hammer will help you with this.

When performing dismantling work, do not forget about your own safety. Put on your glasses, mask, and gloves on your hands.

The next step is to clean the entire surface. Remove large and small debris, sweep away dust and sand (or vacuum). Then start leveling the base. If dismantling results in large depressions or bulges, then leveling should begin with them. The bulges are knocked down with a chisel, and the depressions are sealed with cement-sand mortar. Then a sand-cement screed is laid on the concrete floor and leveled. At each stage, check the levelness using a level. Unevenness is allowed in the range from 0.5 to 1 cm.

If the room has wooden floors, then the leveling technology is different. First of all, the boards must be impregnated with a special oil-based paint. When the surface is dry, a layer of waterproofing is laid. Then a reinforcing mesh is mounted to a height of 4-5 cm (for this you can use nails that are not completely driven into the floors). And only after that the entire area is filled with a leveling mixture (sand-cement mortar).

In rooms with wooden floors, it is allowed to use thick plywood (at least 12 mm thick) as a backing. But the sheets must be laid on a surface without significant unevenness. Otherwise, under the weight of the tiles and the adhesive mass, the plywood may bend and break.

We carry out the markings

Laying ceramic tiles on the floor begins with markings. The first step (especially if you are installing for the first time) is to do a dry layout. The tiles are placed in place without adhesive. This way you can calculate everything (where you need to cut, where difficult angles are formed, etc.). When laying out, do not forget about future seams between the tiles.

There are two main ways to lay out slabs.

The easiest one is to start from one far corner of the room. This method is considered the fastest. This is how all novice tilers lay, or if they have to work in small narrow rooms, or rooms with complex geometry.

The second method is more complex - laying from the middle of the room to the sides. This is how tiles are laid in large and free rooms. In this case, the room is divided into four equal parts. The first line is drawn from the middle of one wall to the opposite, the second is also in the middle, perpendicular to the first. Laying begins from any corner formed in the center of the room. In this case, you will have to cut the tiles around the perimeter of the room. When using this method of installation, a more attractive pattern is formed.

You can also choose the direction of laying the tiles. Can be laid diagonally or in the usual straight way. The first one looks much more beautiful, but to create it you need to have experience in such work. That is why the second installation method is much more common.

Whatever method you use, you will still have to cut the tiles. It is important to remember one recommendation here. Try not to cut strips that are too narrow, as they will look bad. Of the full tile, at least 20 percent of the area should remain. Also make sure that the most visible area is made of whole tiles.

Laying ceramic tiles

Now let's take a closer look at how to lay floor tiles. First of all, prepare the glue. If you purchased a ready-made mass, then carefully read the instructions. If you like dry glue, then you need to dilute it with water (also according to the manufacturer’s recommendations).

Since the process of laying tiles is quite long, it is necessary to dilute the adhesive mass in small portions. Otherwise, it will simply dry out and increase your financial costs.

Work is carried out squarely. That is, areas of a square meter are marked and an adhesive mass is prepared for this area. After finishing one area, we move on to the next.

First you need to cover the entire area with primer. This will prevent the formation of mold and make the surface more suitable for high-quality bonding. Depending on the level of humidity in the room, the primer is made from one to three passes. Only after it has completely dried can you begin laying floor tiles.

The surface is slightly moistened, and a layer of adhesive mass is applied to it. Using a notched trowel, the glue is leveled. In this case, you need to ensure that voids and air bags do not form.

A layer of glue is also applied to the back of the tile. This is done using the same notched spatula. You need to cover the entire surface with a thin layer. The tile is then turned over and neatly placed in its place. In this case, you need to apply even pressure over the entire surface.

The tiles are leveled by gently moving from side to side. Horizontal evenness is checked using a building level or using a simple stretched thread. If the tile lies below the desired level, then a little adhesive is added; if it is higher, the excess glue is removed.

A rubber hammer is used to level the tiles flat. With its help, accurate blows are delivered. This way you can move the tile to the desired place.

An even gap must be left between the tiles. Its accuracy is achieved by using special plastic crosses. They fit into the resulting seam. If the tiles are aligned along the crosses, the gap will be smooth and neat. Such a seam (2-5 mm wide) is needed to prevent the coating from swelling.

Near the walls you will have to cut the tiles. This is done using a tile cutter. A line is carefully drawn along the ruler, and then the tile is simply broken. But this must be done carefully.

Final stage

While working, you need to periodically wipe the already completed area of masonry with a rag. This is necessary to wipe off any remaining adhesive before it hardens. And after laying the entire flooring, you cannot walk on it for at least two days.

After the glue has hardened, you can begin grouting the joints. For this, a special moisture-resistant putty is used. This work can be done using a rubber spatula. But first you need to clean the seams from construction debris and dust.

After all the seams have been rubbed, you need to clean the entire floor of debris with a rag. Then the grout is given a day to dry and you can begin wet cleaning.

This completes the tile laying work. You can learn some tricks and installation techniques by watching videos and photos.

Video

Video material about the features of laying tiles on the floor:

Photo

Ceramic tiles have long been used for flooring. This is a durable, wear-resistant, practical and beautiful material. Of course, only professionals can achieve exclusive finishing. But it’s quite possible to make the floor in the toilet, bathroom or kitchen with your own hands. Be persistent and everything will work out. Even if you break several tiles, the savings will still be many times greater.

What are the characteristics of ceramic products?

- composition of raw materials: from red, white, colored clay;

- manufacturing method: pressed, extruded;

- firing: single, double;

- material structure: porous, dense;

- type of coating: glazed, unglazed.

For deviations up to 10 cm, first apply a leveling cement-sand mixture, and after drying, apply a self-leveling one.

The wrong choice of mixture will cause the surface to crack or be poorly leveled, which will lead to additional costs and wasted time to correct the work.

If you plan to lay tiles over an old tile base, no leveling mixtures will be needed.

Finally, ceramics can be laid on a wooden floor, having previously strengthened it. For preliminary cladding, cement-fiber boards will be required.

Step 3. Purchasing everything you need

So, the layout design has been chosen, the method of preparing the base has been outlined. What materials you will need:

Basic:

- ceramics;

- glue;

- grouting joints (in the vocabulary of builders - fugue);

- impregnation;

- plastic dividing crosses.

Auxiliary (base preparation):

- self-leveling mixture (or cement-fiber boards);

- primer primer;

- roll or coating waterproofing;

- quartz sand;

- degreasers.

What tools will you need:

- glue container;

- electric drill with mixer attachment;

- Master OK;

- spatulas: toothed metal for applying glue and narrow rubber for grouting;

- manual roller or electric tile cutter, as an option - tile cutter, glass cutter;

- tungsten string with diamond coating;

- a hacksaw blade for metal or a jigsaw for cutting out (for attaching the string);

- a ring bit for drilling holes, or a ballerina drill;

- roulette;

- marking cord;

- pencil;

- square;

- short (up to 300 mm) building level;

- metal rule or level 1.5 m long;

- rubber mallet.

- protective glasses.

Step 4: Preparing the floor

In order for the coating to adhere securely to the base and not fall off or crunch underfoot, the base should not be loose or flexible (unsteady). After the revision, determine whether something needs to be done with the base, and if so, then what exactly. Based on the results of the audit (step 2), a decision is made on how to strengthen the foundation.

Concrete base:

Loose, flaking areas are scraped off manually (with a chisel) or with a hammer drill with a flat attachment. Clean the surface from dust, dirt and grease deposits using chemicals. Level the base using a solution based on one or another leveling mixture.

Loose, flaking areas are scraped off manually (with a chisel) or with a hammer drill with a flat attachment. Clean the surface from dust, dirt and grease deposits using chemicals. Level the base using a solution based on one or another leveling mixture.

Apply a layer of liquid primer. Glue roll or coating waterproofing. Sprinkle a thin layer of quartz sand on top (for better adhesion of the adhesive composition to the base).

In order to lay a new coating on the old tile, sand the base using a rotary or surface grinder (round metal brush, abrasive wheel, abrasive belt).

On a wooden floor:

The base is covered with gypsum fiber sheets (GVL) 20 mm thick (for dry rooms) or cement particle boards (CSP) 10 - 15 mm thick (in rooms with high humidity). The joints should not be located between the boards; for gypsum plasterboard they are filled with special glue, for CBPB - with elastic polyurethane mastic.

The base is covered with gypsum fiber sheets (GVL) 20 mm thick (for dry rooms) or cement particle boards (CSP) 10 - 15 mm thick (in rooms with high humidity). The joints should not be located between the boards; for gypsum plasterboard they are filled with special glue, for CBPB - with elastic polyurethane mastic.

Step 5. Marking

The outline of a room is rarely perfectly rectangular. With a monochromatic floor finish, this is not noticeable. Perpendicular tile joints emphasize the unevenness of the walls. How to reduce this illusion? Procedure:

If the walls are fairly straight (the difference in diagonals is no more than 1 cm), draw one of the marking lines parallel to the long side of the room.

Step 6. Preparing the glue

Dry mixture for tile adhesive is sold in 25 kg bags. To seal it, take an open container with a volume of 5 - 10 liters (empty plastic cans for paint, putty and other materials are suitable). The main thing is that the inside is dry, clean and free of grease.

Pour a certain amount of water into the container, then add the appropriate amount of dry mixture (the ratio is indicated on the packaging).

Make the first batch small until you feel how much of the solution you can use during its viability.

Take an electric drill with a mixer attachment and mix the contents until the solution has the consistency of sour cream and there are no unmixed lumps left in it.

Take an electric drill with a mixer attachment and mix the contents until the solution has the consistency of sour cream and there are no unmixed lumps left in it.

To prevent the solution from separating, do not set the mixer speed too high.

Let the mixture sit for 10 - 15 minutes and stir again. The glue is ready to use.

Step 7. Styling

You can watch how to lay floor tiles in this video:

We dance from the stove. The first tile is laid according to the markings (step 5) according to the selected layout option. If work starts from the center of the room, choose a quarter of the marking opposite to the entrance, so as not to walk on the newly laid tiles.

Using a trowel, spread the amount of mortar on the floor for 2 to 3 tiles. Using a notched trowel with a cut width of 6 to 8 mm, smooth out the glue. Place the first tile in the corner of the marking, lightly press it on top with your hands or a level, checking its horizontalness with a short level. If necessary, adjust the horizon by recessing one edge of the tile using a rubber mallet or placing an additional portion of glue under it.

Install the next tile close to the first, place dividing crosses in the corners, some prefer to place them upright on the sides of the tile. Check horizontality and relative position with a long level. After the coated surface has been laid out, the next portion of the solution is placed and smoothed.

Install the next tile close to the first, place dividing crosses in the corners, some prefer to place them upright on the sides of the tile. Check horizontality and relative position with a long level. After the coated surface has been laid out, the next portion of the solution is placed and smoothed.

They put a few more pieces in place. After a while it will become clear: how many tiles you manage to put on one portion of the solution, after which the work will go faster. When the time comes to lay additional elements (not whole), they are cut to the required size. Curly cutouts are made for the passage of various pipes. Laying is carried out starting from the far corners of the room and ending at the front door.

Step 8. Grouting the joints

The grout mixture is diluted to a thick paste, after which it is applied into the cracks between the tiles, trying to fill them to their full depth. Only then can you be sure that after some time cavities will not appear on the seams where moisture will penetrate.

The joints are filled with paste using a hard rubber spatula, making cross movements with it.  along the seam from left to right and vice versa, while holding it at an angle of 45° to the floor. Excess fugue is removed with the same rubber spatula, moving it along the seam perpendicular to the coating.

along the seam from left to right and vice versa, while holding it at an angle of 45° to the floor. Excess fugue is removed with the same rubber spatula, moving it along the seam perpendicular to the coating.

After about 20 minutes, the floor is finally wiped with a damp sponge, which is periodically rinsed to remove adhered grout particles. After complete hardening, the surface of the fugue is covered with sealant or impregnation for seams to protect it from moisture.

Subtleties of styling

We invite you to watch a video on laying tiles:

Some tips from the experience of tilers:

- For laying on the floor, it is better to choose ceramics with a matte surface;

- If possible, choose tiles without chamfers (roundings) at the ends. They visually increase the thickness of the seam, that is, if the seam is chosen to be 3 mm, then it will look like 5 - 6 mm;

- When choosing a notched trowel, it is assumed that the thicker the ceramic product, the wider the cutouts should be;

- For more durable adhesion, sometimes the back side of the tile is coated: apply a layer of glue with a notched trowel, and remove it with a flat one (coating “to peel off”);

- This method is also more reliable for gluing large-format products;

- To remove incorrectly laid tiles (especially if they are not located on the edge), special suction cups are used;

- The crosses are taken out without waiting for the glue to set completely;

- Before grouting ceramic products with a rough surface, in order to avoid contamination, they are first coated with a protective liquid;

- Tile seams should be slightly recessed relative to the tiles. To do this, after grouting, the seams are ironed with the end of a metal tube, the diameter of which is slightly larger than the width of the seam;

- Choose the correct time after which the coating can be wiped from the fugue. If you start too early, the grout will spread across the tile; if you wait too long, the grout will harden and you will have to scrape it off, with the risk of scratching the surface.

So, the technology of finishing a floor with ceramics does not present any particular difficulties. The main thing is to follow all the tips and recommendations for tiling work. More confidence in your abilities, and your new floor will delight you for many years.

Ceramic tiles are an almost ideal choice for bathroom flooring. With its help you can create an excellent floor that will last for several decades.

This coating goes well with all types of underfloor heating systems, and its installation technology is relatively simple. Having studied in detail how to lay tiles on the floor, even a novice master can cope with this task.

Ceramic floor tiles, like wall tiles, are sold in a wide variety of options: size, color, configuration, pattern, etc. First you need to decide on the design of the flooring and calculate the required number of tiles.

It is very important not to confuse the type of material when purchasing. It is strictly forbidden to place tiles that are made for walls on the floor. The surface of the floor tiles is specially given some roughness so that feet do not slip on it.

And the elements intended for walls are too smooth.

Installing such material on the floor can result in serious injury as well as unnecessary expense. If you need a ceramic coating with a glossy, smooth surface for the sake of an impressive floor design, you need to find this type of floor tile.

It gives the necessary shine, but at the same time its surface is quite rough and safe.

Ceramic flooring goes well with all types of heated floors. For example, cable systems are simply mounted on the base under a layer of tile adhesive

It is better to buy all the material from one batch at once. It is recommended to purchase several tiles in excess of the calculated quantity in order to create the necessary reserve in case the tiles are damaged during cutting.

Tiles with the same name and article number, from the same manufacturer, but from different batches, often have a slightly different shade, and this will spoil the entire appearance of the floor.

In addition to the tiles, you need to buy glue for its installation. In this case, it is not necessary to make a reserve. At the final stage you will need grout for the seams. This composition can be the same shade as the tile, or a contrasting color.

To lay tiles on the floor, you should stock up on a set of quite accessible tools:

- spatula with teeth;

- plastic cross-shaped dividers;

- building level;

- tile cutter (or glass cutter);

- roulette;

- rubber hammer;

- pencil;

- rubber spatula;

- sponge;

- containers for mixing glue and grout;

- clean rags.

Notched spatulas come in different sizes and with different teeth. There are three types of spatulas based on the type of teeth:

- V-shaped – for mounting thin wall tiles;

- Square teeth – for regular floor tiles;

- U-shaped – for especially large tiles.

The size of the teeth and spatula depends on the layer of adhesive that is supposed to be applied under the tile. This information is contained in the tile and adhesive manufacturer's instructions.

The composition can be applied with a regular spatula, but then it will be difficult to achieve uniform distribution of the glue over the surface of the tile, and the quality of the work may suffer.

Preparing the room and base

Before laying ceramic tiles on the floor, it is necessary to remove from the room everything that could interfere with the work and thoroughly clean the base on which the tiles are to be laid.

The presence of dust, grease or other stains can impair the adhesion of the adhesive solution to the substrate.

Another important part of preparing the room is clearing the floor from the baseboards. In some cases, door trims are also removed.

Of course, it is best to install floor tiles before the doors are installed in the room. In order for the pattern formed by the elements to look beautiful, you should mark out the room, indicating the axial lines that connect the middles of opposite walls.

If you choose a diagonal layout, you will need diagonal guides connecting the corners. After this, you need to lay out the tiles on the floor to evaluate the pattern that will be created when laying them, as well as determine the number and approximate sizes of incomplete elements.

At this stage, you can make the necessary adjustments to the layout diagram.

If floor tiles are to be laid diagonally, it is necessary to place guides not only in the center of the walls, but also diagonally

It is necessary that the base is as even and smooth as possible. Most often, the tiles are laid on a concrete or cement screed, but there are other types of bases that also need to be leveled.

Here are some important points to consider when installing tiles:

- The cement screed must be completely dry before starting work. This usually takes about four weeks.

- The use of hardeners for cement screed impairs the adhesion of the base to the adhesive composition.

- Before starting work, the cement or concrete base must be primed.

- In a newly built house, it is recommended to use a plastic type of base for tiles, since the building can “shrink” over several years. Using a rigid base will result in deformation of the floor covering.

- To seal cracks in a concrete or cement base, a special repair compound is used.

- When installing tiles on a wooden base, it is leveled using fairly thick (12 mm) sheets of plywood.

- If installation on a wooden base is carried out in a room with high humidity, an additional elastic layer is placed on the plywood to compensate for the expansion of the wood under the influence of moisture.

- When installing on a layer of old ceramic tiles, the floor surface should be leveled using sandpaper. This will also improve the adhesion of the old floor to the new floor covering.

Typically, a specialist does not advise laying ceramic tiles on top of the old layer. This significantly raises the floor level, and the amount of installation may not be too high.

This method is used very rarely, for example, when dismantling a ceramic floor covering can lead to significant damage to the underlying base. A concrete slab damaged during dismantling is not difficult to repair using repair compounds.

Of course, removing old tiles, filling uneven areas and laying new tiles will require more time and expense, but the quality of the work will be higher.

An important point - tile adhesive

Tile adhesive is sold ready-made, and also as a dry mixture, which is prepared immediately before installation.

The cost of ready-made glue is usually significantly higher than its dry counterpart. Construction stores offer several types of dry tile adhesive mixtures:

- base mixture - for treating bases that are well leveled and cleaned;

- universal composition - suitable for almost any tile and any base;

- reinforced version - recommended for large tiles, has increased adhesion to various substrates;

- composition for working on complex substrates - can be used for laying tiles on glass, metal and other non-traditional substrates, it is used extremely rarely.

Before preparing the solution, you must carefully study the manufacturer's recommendations and then follow them exactly. Be sure to pay attention to the lifetime of the finished solution.

It is worth preparing exactly the amount of glue that will be used during this period. To prepare the composition, the mixture is usually poured into a container with water, and then mixed thoroughly.

Technology and procedure for performing work

The installation of floor tiles is clearly shown in the following video:

Even at the preparatory stage, you should decide on the pattern that the tiles will form on the floor. Single-color tiles can be laid with matching seams or staggered, along the walls or diagonally.

Multi-colored elements are sometimes placed in a checkerboard pattern. You can also select a set of elements that forms an image. It all depends on the imagination of the apartment owner.

Experts recommend choosing a pattern so that its center line coincides with the center line of the window (if the bathroom has a window or a wall image imitating it). This detail will make the entire design of the room more harmonious.

It is also necessary to carry out calculations. We can suggest you use our free online calculator:

You should start laying floor tiles from the wall, which is in plain sight, so that the elements that have to be cut are hidden under pieces of furniture or plumbing fixtures. The fewer cut elements in the selected layout, the faster all work will be completed.

The optimal air temperature for laying tiles is approximately 20 degrees. Too high or too low an air temperature can negatively affect the properties of the adhesive composition. In summer, work on installing tiles is carried out early in the morning or in the evening, and during the heat of the day they take a break.

First, glue is applied to the base. First use the flat side of the spatula, turning it at an acute angle. In this case, the glue should be applied with some force so that all the irregularities and recesses on the base are well filled.

Then the teeth are drawn along the layer of glue so that grooves appear, thanks to which the glue is distributed as evenly as possible. During the process of applying grooves, you should not change the angle of the spatula so that their depth remains the same over the entire surface.

The result should be a layer of tile adhesive, the thickness of which is greater than the height of the trowel teeth.

Using a notched trowel, grooves are applied to the layer of adhesive composition, the depth of which should be the same. To do this, the spatula should be held at the same angle to the surface.

The tile is placed on the area treated with glue and pressed well so that the voids in the grooves are filled with glue.

If a little adhesive appears on the surface, it should be removed immediately with a clean cloth. If this is not done immediately, the glue will harden and will be much more difficult to remove. There have been cases when careless cleaning of dried mortar left deep scratches on the tiles.

To ensure a tight and uniform fit of the tile to the base, each element is immediately tapped with a special rubber hammer, moving from the center to the edges.

To ensure that the tiles adhere to the floor evenly and reliably, it is necessary to carefully tap each tile after laying it on the adhesive layer with a rubber hammer

Cross-shaped dividers should be installed between the laid tiles. They help create a perfectly uniform seam between the tiles, as well as control their position relative to each other.

From time to time it is necessary to check the resulting joint between the tiles, which should be smooth. In addition, using a building level, it is necessary to constantly monitor the slope of the tiles.

It can be adjusted using the amount of adhesive placed under the tile. Typically, the installation of tiles begins with solid elements, and then fills the remaining space with tiles cut to size.

During the process of laying floor tiles, you should regularly check the position of the ceramic floor using a building level and, if necessary, adjust it

It is enough to use a tile cutter or glass cutter to draw a straight line along the tile, then place it on a table or other convenient flat surface so that the cut coincides with the edge.

After this, you need to press on the hanging part of the tile to break it exactly along the cut line. Sometimes it is more convenient to simply place an equal stick under the cut line, and then press lightly on both sides.

Separators in the form of crosses greatly facilitate the process of installing floor tiles, ensuring an even seam between them. About half an hour after installation, the dividers can be removed

It is more convenient and reliable to cut thick floor tiles with a tile cutter, since this tool, due to its design features, makes it possible to make a cut to a greater depth than when working with a glass cutter.

To make a shaped cut rather than a straight one, metal cutting tongs are sometimes used. A narrow strip can be separated from the tile using pliers, but you must be very careful when doing this.

The best way to cut ceramic floor tiles is to use a tile cutter. This device allows you to make an even and neat cut on thick tiles.

To drill a neat hole in the tile, you should use a special tool called a “ballerina”.

However, it is still not always possible to avoid cracking of the element. Professionals recommend carefully removing some of the glaze from the tile at the drilling site. To do this, use a hammer and a suitable object with a sharp edge, for example, a tap.

Gentle tapping makes it easy to chip off and remove part of the coating. After this, you can use a hand drill with the drill bit clamped in the chuck for drilling.

Grouting the joints between ceramic tiles is done with a special rubber spatula or “trowel”. The color of the grout may match or contrast with the color of the floor

After all the tiles have been laid, you should wait a while for the glue to harden. After this, you can start grouting the joints. The mixture is applied to the tiles in the area of the seams with a small rubber spatula so that they are filled.

Excess grout is also removed using a spatula. After this, you need to wait again until the grout dries. Then the tiles need to be washed from any remaining grout.

A bucket of clean water and a rag are usually enough for this. Now the process of laying floor tiles can be considered complete.

No matter how diverse the range of available finishing materials pleases us today, ceramic tiles, although they are among the venerable “veterans” of the construction market, are by no means in a hurry to lose their leading position in popularity. It occupies a very specific “niche” - this material, thanks to its unique performance characteristics, is used for external and external work, for residential and technical premises, for finishing floors and walls, facades and hydraulic structures, adjoining buildings and even garden design elements.

Ceramic tiles have practically no competitors in the field of finishing rooms with a pronounced high level of humidity - bathrooms, bathrooms, kitchens, etc. The strength of ceramics allows it to withstand high loads, therefore, when tiling floors in such rooms, preference is most often given to it, since for all its positive qualities it is also very affordable. And another important advantage is the relative ease of installation: if you thoroughly understand the intricacies of how to put tiles on the floor, get a little practice in your hand, and show diligence, then you can easily cope with such work yourself.

But before tackling styling issues, it would be logical to consider the problems of its correct selection.

When going to the store to select and purchase the necessary material, the apartment owner should “arm” himself with basic knowledge of what kind of tiles are usually on sale.

Choosing floor tiles based solely on their decorative qualities is an extremely frivolous approach. In a good store, trained sales consultants can be of great help and can tell you which tile model is intended for what purpose. But it’s better to be able to navigate the icons and pictograms, which can tell a lot on their own. The most common The symbols that may appear are shown in the table:

1 - This is a tile with pronounced frost-resistant qualities. It is suitable for the floor of a porch, veranda, balcony or loggia. There is no point in spending money on purchasing such tiles for further flooring in a heated room.

2 – A foot on an inclined plane is a symbol of the anti-slip properties of the tile. For rooms with high humidity (bathroom, kitchen) or for hallways, where shoes often carry moisture from the street, this is a very important criterion. Often this icon is accompanied by a digital indicator - this is the coefficient of friction. For the mentioned premises, the optimal choice would be slightly rough tiles with the specified coefficient not lower than 0.75.

3 – A sign in the form of a diamond (sometimes found with an image of a drill) – the tile has increased characteristics of surface strength and resistance to accented impacts. Good quality for kitchen floors - accidentally dropped dishes will not cause serious damage to the flooring.

4 – A similar pictogram is always accompanied by a numerical value - this is the thickness of the ceramic tile. For laying on the floor, a material with a thickness of about 7–8 mm is usually purchased.

5 – Ultimate bending strength of a single tile. This parameter is determined based on the results of bench tests, and the higher it is, the better the quality of the material (for example, for porcelain stoneware this indicator is much higher than for ordinary tiles). However, the tiles on the floor should be laid so that the bending load is minimal - tightly and evenly to the surface, without air bubbles, shells, etc.

6 - The palm-shaped icon indicates that this ceramic tile is intended exclusively for walls. No matter how beautiful and durable it may seem, you cannot purchase it for laying on the floor.

7 – But the image of the shoe print speaks for itself - this tile is intended specifically for the floor.

8 or 16 are indicators of the resistance of ceramic tiles to abrasive and abrasive loads. In accordance with the international standard PE1 (EN ISO 105645.7), there are 5 wear resistance classes:

| Wear resistance class according to PE1 (EN ISO 105645.7) | Application area |

|---|---|

| I | Such tiles are suitable for rooms with minimal load, where there is never intense movement of people (for example, a bathroom, toilet). Street shoes are not worn in such rooms, and they are not close to the exit to the street. |

| II | This tile is for rooms where people also wear slippers, but the intensity of traffic is somewhat higher. |

| III | The wear resistance of this class allows the use of ceramic tiles in hallways or kitchens. |

| IV | High-strength tiles for rooms and halls with intense load - entrances, shops, public places, offices, etc. There is no point in using it in apartments or private houses. |

| V | The highest class of abrasive strength, applicable for coatings with extremely high intensity of movement of people and even some types of transport. Scope of application: train stations, large supermarkets, warehouses, industrial premises, etc. |

9 – This pictogram indicates that the ceramic tile has undergone a double firing procedure. This material usually has a glossy glazed surface and is more suitable for installation on walls. In addition, double firing technology implies increased porosity of the ceramic, which means a decrease in its mechanical strength and increased water absorption.

10 – The icon in the form of a chemical flask indicates the increased resistance of the tile surface to acids, alkalis, and other aggressive substances, including any type of household chemicals. The letter indicator of this material property is “AA”.

11 - If you come across such an icon, then you need to be careful in choosing tiles - there may be tiles of different shades in one box.

12 – Notwhich expensive types of ceramic tiles can be produced with the inclusion of noble metals: silver (Ag), gold (Au) or even platinum (Pt).

Pictograms 13 ÷ 15 inform about the parameters of the factory packaging of ceramic tiles. So, in the example given, symbol 13 indicates that the gross weight of the box is 19.00 kilograms, icon 14 means that one package is enough for 1.42 m² of floor area, and symbol 16 means that there are 24 tiles packed in the box.

Some of the specific properties of the material will be indicated by the pictograms indicated in the table under numbers from 17 to 21. Such ceramic tiles are intended for special operating conditions. These could be train stations And and airports, medical institutions, industrial enterprises, hotels, sports facilities. There is no point in purchasing such tiles for flooring in a private house or apartment.

What other points should not be overlooked:

- If the tiles are planned to be laid on the floor of a bathroom, shower room, kitchen or other room with high humidity, then a material with a minimum (not higher than 3%) water absorption coefficient is required.

- The linear dimensions (length and width) of the tile also matter. Of course, the larger the tile, the faster it can be laid. However, for rooms with a small area and complex floor shapes, oversized tiles will not be suitable - there will be a lot of waste. And large tiles will look somewhat ridiculous in such rooms. In addition, we must not forget that carefully laying large tiles is much more difficult.

- If you purchase several packs of ceramic tiles, you must definitely select the product from the same batch.

This is necessary for two reasons:

— Firstly, even a completely identical model of tile, but from different batches, may have slight deviations in shade. In a store environment, it is quite possible that this will not even be noticeable. However, after laying such a covering on the floor and under normal lighting, such a difference can greatly spoil the intended interior appearance of the room.

Different batches may also differ in calibration - the linear dimensions of the tiles

— Secondly, fluctuations in the linear dimensions of the tiles cannot be ruled out. It is clear that cutting of material in production is carried out under the control of precision electronics. But it still remains ceramic, and there may be small errors, so calibration of the finished products must be carried out. One batch should always contain tiles of the same calibration, and the difference between different batches can even be several millimeters. When laying such tiles on the floor, especially in large rooms, inconsistencies may occur that are noticeable to the naked eye.

- Be sure to check the packages for broken, cracked or chipped tiles on the surface. Sellers may convince you that marriage is an inevitable phenomenon, and you need to come to terms with it. No, it’s not necessary, you pay your money for a quality product.

- It is generally accepted that a certain reserve should be purchased, 10% more than the area of the room. This will be spent on “cuts” and in cases of compensation for any annoying misunderstandings. It must be remembered that it will not always be possible to buy additional tiles later to make up for the missing quantity - this has already been mentioned when talking about batches.

By the way, if you plan to lay tiles, then the reserve can even be increased slightly - up to 15%. With this technology, it is more difficult to adjust the material along the walls, there is more waste left and, in addition, there is a much higher probability of making some mistakes due to inexperience.

Prices for ceramic tiles

Ceramic tile

How to lay tiles on a concrete floor

The process of tiling a floor with ceramic tiles can be divided into four main stages:

- Preparing the surface for installation.

- Carrying out the necessary markings, drawing up a work plan.

- Laying ceramic tiles with adhesive mortar.

- and finishing works.

Preparing the floor surface for laying tiles

The requirements for the base for laying tiles are, in principle, simple - it must be strong, stable, and provide good adhesion to the adhesive composition. How is this achieved?

If we are talking about a concrete base, then first it is necessary to carry out a thorough inspection of the old screed on which the tiles are planned to be laid. There is no need to be lazy - you should tap every centimeter of the floor to make sure there are no unstable areas.

- First of all, its horizontalness is checked - if this condition is not met, then pouring a new screed simply cannot be avoided. If the evenness is satisfactory (differences are no more than 2-3 mm), then the old coating can still serve, provided, of course, that it is stable.

- If, during a control inspection, places of screed peeling, concrete crumbling, or deep oiling are identified, it is necessary to remove them right down to the “healthy” surface, both in width and in depth. Wide cracks and crevices need to be cut to a width of 10 - 15 mm.

- There should be no traces of paint, oil products, fats, or remnants of the old coating on the surface - everything is cleaned off to clean concrete.

- All protrusions must be cut down - if you can sometimes look at a small depression “through your fingers”, since it will still be filled with glue during the laying process, then even the smallest bump will make even laying simply impossible.

- After this, a thorough cleaning is carried out with dust removal of the surface. In order for the repair suction to adhere well, it is necessary to prime all areas to be repaired and allow the primer to dry completely.

- A repair composition is being prepared - it can be a “classic” cement-sand mixture in a ratio of 1:3, but it will take quite a long time to dry.

The finished and completely cured screed is also primed twice, after which you can proceed to further work.

Prices for various types of screeds and self-leveling floors

Screeds and self-leveling floors

Marking the floor for laying ceramic tiles

Ceramic tiles should become a decoration of the room, and this will be possible only if their location on the floor is planned correctly. A sloppy, slanted tile can completely decorate an interior.

There are many techniques and methods for placing ceramic tiles on the floor - it is impossible to consider all of them in the scope of this article - this is a topic for a separate publication. But even the simplest, “classic” method requires precision and accuracy.

Starting to plan installation from the wall is very risky, since the slightest defect will grow with each successive row, and it will be very difficult to eliminate it. Therefore, the reference lines and the first rows of tiles are usually located approximately in the center of the room.

The first reference line is usually drawn along the room. To do this, in two places, at the beginning and at the end, carefully measure the distance between opposite walls and mark the midpoints. They are connected by a straight line (usually this is done using a coated cord), and a longitudinal baseline is obtained.

Now you need to draw a second one, perpendicular to the first, also approximately in the middle of the room. It is very important that strict perpendicularity is maintained. In order to avoid mistakes, and this is quite possible when using a square and a ruler, you should definitely check the right angle using the formula of the famous “Egyptian triangle”: 3² + 4² = 5². According to the Pythagorean theorem, it is a triangle with legs divisible by 3 and 4 and a hypotenuse divisible by 5.

For example, we measure 900 and 1200 mm from the intersection point of the legs. We connect the marked points with a segment, and its length should be exactly 1500 mm - no more no less.

Once the lines are drawn and their perpendicularity is checked, you can think about how to place the rows of tiles and where to start the layout. We remember that the drawn reference lines are not at all a “dogma” for starting masonry - it will not be difficult to carry out a parallel transfer from them in any direction.

For example, if the entrance door in a spacious room is located exactly in the center, then you can lay out the first rows of tiles - along the laid reference lines. The principle is this: so that when entering the room, a flat area is presented to the eye, without cuts or adjustments. (see item “a” in the figure).

But in a room with a small area, with the exit shifted to the edge (pos. “b”), and even possibly having a complex shape or stationary obstacles, the start of masonry can be smestyle to a free “patch” - from here it will be much more convenient to work in all directions, but it is the entrance that will turn out to be the “front door”.

In any case, you should never be lazy - you should carry out a control laying of the central longitudinal and transverse rows of ceramic tiles “dry”, without using mortar, but leaving the planned gap between adjacent tiles.

Do not neglect the initial “dry” laying of the tiles - this will allow you to evaluate the options for its location

This simple procedure will allow you to visually assess the future picture, measure distances, and finally decide on the laying scheme, that is, settle on one of the principles:

1 – in a small room, for example, in a bathroom or kitchen, you can take two walls from the entrance (green arrows) as the “starting line”, provided that they are exactly perpendicular. In this case, the entire visible part of the room will be lined with intact tiles, and the cut edges will be hidden under furniture or plumbing equipment.

2 – the laying is carried out from the center in such a way as to place the maximum possible number of whole tiles on the floor, leaving narrow areas for addition with fragments (brown arrows). Beneficial in terms of material savings. However, for reasons of masonry quality, it is advisable to leave areas no narrower than ⅓ of the width of the tiles near the walls.

3 – the arrangement with a minimum number of whole tiles in a row, but with expanded fragments along the walls (blue arrows) looks a little more impressive. This coating looks more complete, and from an operational point of view it is more reliable than No. 2.

4 – laying diagonally – will help hide the curvature of the room. Among the disadvantages is a more complex design, especially in terms of preliminary marking and fitting of tile fragments, more material goes to waste.

If you have decided on this, then you should immediately outline what scheme will be followed work is being carried out– from the far corner to the entrance, or with dividing the space into several areas in straight rows, followed by filling them.

You can also “fill” space in different ways. So, some masters do the styling in an orderly manner. Others prefer the “ladder” scheme with a sequential increase in the number of simultaneously laid rows.

“Filling” the space can be done linearly, or, as shown in the figure, in steps

By the way, there are supporters of laying ceramic tiles on the floor “at random” or even chaotically - sometimes this is included in the design intent of the room decoration. But in an ordinary home, they still prefer to limit themselves to a straight laying pattern, “seam to seam”.

Laying tiles on the floor

- So, we prepare the necessary tools and materials for installation.

— For work you will need spatulas, ordinary, with a width of 100 to 250 mm, and serrated ones, with a height of the created furrow of 8–10 mm. To grout joints, it’s a good idea to get an elastic rubber spatula.

— You will need a construction mixer or a drill with an attachment for mixing tiles and an appropriate container for the same purposes.

— Always have a building level at hand.

— In some cases, you may need to use force to get the tiles into place. It is convenient to use a rubber hammer for this purpose.

— You should immediately think about how the tiles will be cut (more on this below).

— It is necessary to create a supply of calibration crosses of the required thickness, plastic wedges for leveling the height.

— In order not to carry dirt, you need to have a supply of clean rags and a sponge for wiping the solution from the front surface of the tile.

- Probably, nowadays no one thinks about making tile adhesive on their own - it can always be purchased in the store. When choosing, you need to check the purpose of the composition - in addition to the usual ones, intended for most interior spaces, there are specialized mixtures, intended for rooms with high humidity conditions, for outdoor use, particularly resistant or for so-called “complex surfaces”, for “warm floor” systems, etc.

The glue is diluted by gradually adding the dry mixture to the amount of water specified in the instructions, with constant stirring using a mixer or drill. The composition should be absolutely homogeneous, without lumps, of a fairly dense consistency - so that the ridges created with a notched spatula do not spread.

After obtaining the consistency of the composition necessary for work, it is left to “ripen” for 5 minutes, then mixed again for 2-3 minutes - and you can begin laying.

You should not prepare too much mortar at once, especially if you have no experience in laying ceramic tiles. Its “life” is limited - this is necessarily indicated in its instructions. If the glue begins to noticeably thicken during work, you will have to throw it away - you cannot dilute it with water a second time - it will lose its qualities.

- Novice craftsmen, apparently having listened to old, irrelevant advice or read about it somewhere, soak the tiles in water before laying them on the floor. In this way they are making a grave mistake.

A similar approach is possible if the tiles are laid on a regular cement-sand mortar, and even then - not in all cases. And all modern building mixtures - adhesives for ceramic tiles - are designed for application specifically to a dry surface. Excess water will significantly reduce the performance of the glue, and the tiles will begin to “dance” and fall off over time.

Therefore, before laying the first tile, carefully read the instructions for using the purchased tile adhesive again - everything is probably indicated there.

- Where to apply the glue - on the floor or on the tiles? There is no consensus on this issue. Some people like to apply it to tiles - the marking lines on the floor remain intact.

On the other hand, it is more convenient to immediately coat a significant area of the floor, and then concentrate on laying out the tiles evenly (of course, if you have some experience, otherwise you may not have time).

Another option is to pre-coat the floor surface with glue.

There is a third tip - coat both here and there, but lay the tiles in such a way that the direction of the ridges made with a notched trowel on the floor and on the tiles is perpendicular - this ensures that all cavities are filled and maximum adhesion is ensured.

- After coating the tile with glue, it is laid on the surface in the right place, pressed tightly to the floor, its location relative to the reference lines is controlled, as well as the horizontalness of its upper plane in the longitudinal and transverse directions.

- The work continues in the same order, with the obligatory installation of calibration crosses - they will allow you to clearly maintain the required gap between the tiles.

When adjusting each tile, be sure to check its horizontalness using a building level. The necessary adjustments are immediately made - adding or removing a solution, inserting a small wedge, etc.

- It is necessary to ensure that there is no excess glue left in the gap between the tiles - this space will be needed to fill the seams. So it is better to remove the glue immediately, as it will be very difficult to do later. Together with that, you should immediately remove mortar stains from the front surface of the tile with a rag or sponge, without allowing them to dry.

- Spacer crosses are left between the tiles until the mortar initially sets. Then, when the tile has already become immobile, the crosses need to be removed - you cannot leave them in the seams until the glue has completely hardened, since then there will be difficulties with removal.

Video: visual lesson on laying tiles on the floor

- Modern devices for quickly laying tiles - the so-called leveling systems - are very convenient to use. The kit includes rack clamps (disposable items) and wedges (can be reused).

— After the first tile is laid on the glue, pressed well and inserted level, two clamps are installed on each of its sides so that their heel goes under the tile. The thickness of the clamp leg will determine the size of the seam. The clamps are installed at a distance of approximately 50 mm from the corner.

Clamp stands installed...

Then the next tile is laid. The wide heel of the clamp also appears underneath it.

...then the next tile is laid...

A wedge is inserted and threaded as far as possible into the clamp, where it is fixed with its ribbed surface on the hooks. It is very important that the wedges are always inserted from the side of the previously laid and leveled tiles.

... the wedges are inserted until they stop and are completely fixed.

— Thus, the lower, smooth edge of the wedge “pulls” the surface of the next tile ideally into the plane of the already laid one. True, no one can cancel control using a level.

— The wedges should remain in this position until the glue dries completely. Then they are removed with light side blows using a rubber hammer. The design of polymer clamps is such that they can withstand tensile loads, but immediately break off when exposed to a fracture. Below, under the tiles, remain only broken heels.

— Wedges, as already mentioned, can continue to be used, and broken holds can be disposed of.

Video: laying tiles using a tile leveling system

Tile cutting

Previously, we were talking exclusively about laying entire tiles, but in practice there are never cases where everything is limited to this. So now it's time to consider the problem of cutting tiles.

- It is recommended to install the fragments not immediately, but a day later after the main part of the floor. During this time, the glue will have set well, and it will be possible to accurately measure the required dimensions.

- When marking tiles for cutting positions, we must not forget about the joint interval - an allowance must be made for it.

- There are several ways to cut ceramic tiles:

1. The most convenient way is to use a tile cutter, a tabletop tool that gives an even and precise cut. It is enough to place the tile with a marking line along the central protrusion, move the roller away from you with force along the surface of the tile, and then, resting your paws on the surface of the tile on both sides of the drawn line, press the lever down.

The most convenient tool is a tile cutter

With even a little experience of the master, there are practically no defects in such cutting.

2. A manual tile cutter is a fairly convenient tool, but it requires more dexterity from the worker.

First, the roller is drawn along the intended risk line. Then the tile is clamped so that the tile cutter is exactly on top along the axis of the line cutting. Movement with your hands - and the tile should split into two parts.

Cutting is carried out in the same way using a regular glass cutter, with the only difference being that the breaking is carried out on the edge of the workbench, or with the help of a glass placed on the bottom of the workbench along the line. cutting metal rod (nail or wire).

With all the advantages of manual and tabletop tile cutters, they allow you to cut tiles exclusively in a straight line.

3. Sander with a diamond disc - this approach is especially good when cutting tiles at an angle or creating complex shapes is required. The main difficulty here is to ensure reliable fixation of the tiles when working with an angle grinder so that they do not fly out or crack.

Tiles can be precisely cut to size using a diamond grinder

The tile can be cut straight through - when parts of a complex configuration are required. If straight, long sections are cut off, then the integrity of the top enamel layer can only be damaged - then it will be easy to break the tile along the intended line.

Particular attention to precautionary measures - the eyes and face must be covered with a mask, so how is it possible scattering of small hot fragments of ceramics.

4. Small areas of tile can be removed using pliers.

In this case, on the area to be removed, it is advisable to apply a fine mesh with a glass cutter roller. Then, using pliers, they carefully break out very small fragments, gradually bringing the tile to the desired size.

If necessary, any minor unevenness left after cutting can be removed using a block wrapped in coarse (80) sandpaper. If the teeth are large, they can be “corrected” with pliers. If there is a pronounced sharp edge left, then it is better to first process it with a round file.

The process of laying cut fragments, in fact, is no different from what was described above.

When cutting tiles and laying their fragments, special care should be taken. Ceramics can crack not along the intended line, which means there is a high probability of getting a cut injury to your hand when pressed. In addition, the broken edges may have extremely sharp edges that can cause very deep cuts. All work should be performed only with protective gloves.

Sealing seams

After the entire floor area is covered with ceramic tiles, you can proceed to grouting the joints.

- First of all, you need to check the condition of the seams again - they must be cleaned to their entire depth and width.

- Getting ready jointing solution - grout. It can be cement-based or a two-component epoxy composition.

1. In domestic conditions, cement grouts (so-called class WITHG 2 according to EN 13888).

Cement grout for joints

They are sold in stores in the form of hermetically sealed dry mixtures and can have different colors - you can always choose the color that best suits the overall design. They are most often mixed with water to the desired consistency. But for rooms with high humidity or for floors with a high level of load, it is still recommended to use a special latex additive to dilute the composition - the floor surface will only benefit from this.

2. Recently, epoxy-based grouts (class RG according to EN 13888) have been rapidly gaining popularity. These are two-component compositions that are prepared immediately before starting work on filling the seams.

The “lifetime” of such a composition is short, so it is prepared in small portions to ensure that it is used before hardening.

Epoxy grouts are more durable, resistant to chemicals, they are much more flexible and will not crack over time. These compositions have a much wider range of shades (including bright, saturated colors), and in addition, many similar grouts are sold with special effects - sparkles, fluorescent glow, etc.

The only significant drawback of epoxy grouts (apart from a certain difficulty in properly preparing the working composition) is the still very high price, which greatly limits the scope of their use.

- The finished composition is scooped onto a rubber spatula or rubber float and applied with force to the seam area, usually in a direction of 45 degrees from the seam line. This trajectory will ensure the most complete and dense filling of the joint space.

- After the joints are filled, it is necessary to immediately remove the excess mixture from the surface of the tile - this will be much more difficult to do later. Usually this is started when a white coating appears on the grout remaining on the surface of the tile - it begins to dry out (usually after 20 - 30 minutes).

To do this, take a foam sponge, well washed and wrung out, and use it to remove the remains of the fugue. The movements are usually the same as when grouting - 45 degrees to the seam line. At the same time, you must try not to touch the seams, so as not to wash out the fugu from there. The sponge should be washed thoroughly as often as possible, with constant changes of water. By the way, water plays a dual role here - it both washes away contaminants and participates in the hydration of the cement composition of the grouting material.

After 3 — After 4 hours, you can rinse the surface again using a foam sponge. Then, when the floor dries after washing, the remaining light cement deposit can be easily removed by wiping the tiles with a dry, clean, soft rag.

After this, the ceramic tiles will already take on their “ceremonial” appearance, and it will be possible to say that the process of laying it is completed.

Prices for grout for joints

Grout for joints

Video: option for grouting joints on a tiled floor

However, if the cladding was carried out in a room with high humidity or with intense loads on the surface, then it is recommended to carry out another simple operation - coat the seams water repellent.

This is done very simply - the composition is generously applied to the seams with a thin brush. This treatment will give the fugue composition water-repellent properties, which will significantly increase the service life of the ceramic coating, prevent dampness from accumulating in these places, and make cleaning easier.

When the water repellent is absorbed and dries, you can put the final order in place. You need to thoroughly rinse the floor with clean water - and we can assume that the entire multi-step process of laying tiles on the floor is over!