Hand-held copier for a router with your own hands, drawings. Do-it-yourself copy-milling machine - we create reliable equipment! Milling and copying machine for wood "Duplicarver"

Very often in our lives there is a need to make a copy of some object, so the availability of copying equipment is a modern need for many enterprises. And we will not be talking about copy printing equipment, but about copy milling machines.

They serve to create objects that closely replicate the original design. The equipment makes it possible to produce parts in large quantities, ensuring high processing speed.

1 Features of milling

Milling is one of the methods of mechanical processing. The procedure allows for finishing, roughing and semi-finishing of various surfaces of workpieces made of wood, plastic, cast iron, metal (ferrous and non-ferrous).

Milling has high productivity, making it possible to create objects of the required geometric shape.

Milling can be organized in two ways:

- down milling, in which the directions of feed and rotation of the cutter coincide;

- up milling, in which the feed is opposite to the direction of rotation of the cutter.

Using cutters equipped with modern cutting materials, you can carry out processing, replacing the grinding procedure.

A woodworking milling machine, including a mini modification, is used for processing the surfaces of planks, levers, covers, cases and brackets of simple configuration, and the surfaces of cabinet objects.

Allows you to apply 3D or 4D carvings. One of the most popular brands of domestic origin - Duplicarver.

Milling machines come in two categories:

- specialized;

- general purpose.

The last group is continuous milling equipment, non-cantilever, cantilever, longitudinal milling. The first group is copy-milling, key-milling, slot-milling, gear-milling, thread-milling. There are full and mini models.

1.1 Purpose of the machine

A copy milling woodworking machine is used to carry out copying work on a plane and in volume, to engrave patterns, inscriptions, ornaments, shaped profiles, as well as to implement simple milling tasks.

Despite the simplicity of the machine, it allows you to create incredibly complex patterns. It can be mini or full-size.

The equipment allows you to perform various milling operations using carbide and high-speed tools. Can make threads. The machines are used in small and large-scale production. Can work in 3D mode, if appropriate equipment is available, CNC. Duplicarver models are very popular.

The machine allows you to create:

- blanks and models;

- Press forms;

- various stamps;

- cams;

- forms.

The equipment can also be used for:

- drilling holes for metal hinges, handles, latches, locks;

- production of frames for mirrors;

- channels of different sizes on profiles.

The Duplicarver wood milling machine allows you to mill curved parts by copying a template from which the shape of the future product is copied. Thanks to the use of templates the influence of the so-called human factor is excluded, therefore the finished products have an identical shape. This is largely ensured by CNC.

Not only a template sample can be used in the work; subsequent products can be made according to the sample of the first one. To increase accuracy, the machine should be supplemented with a copying device called a pantograph.

It may have a different design, but it has an important function - accurate transmission along the profile of the movement of the copy head to the cutting device. Therefore, high precision of the thread is achieved when applying it.

2 Machine design

The Duplicarver milling machine uses a carbide cutting tool – a milling cutter. It reproduces the surface or contour of the copier on the product.

This machine master device has a hydraulic, mechanical and pneumatic connection with a tracking system responsible for the direction of the cutter. On the one hand, it acts on the amplification device, on the other, it affects the executive body.

The copier is a flat template, outline drawing, reference part, spatial model. Copier - photocell, finger, roller or probe. Samples can be parts made of wood, plastic or metal. The copier and the workpiece being processed are located on a rotating table.

The executive body of the Duplicarver machine is a differential, electromagnetic clutch, solenoid, screw, spool. Electro-optical, hydraulic or electromagnetic relays can be used in amplifying devices.

The speed of movement of the tracking device determines the accuracy of the profile and the surface roughness of the product. An accuracy of 0.02 mm and a roughness of No. 6 can be achieved. The Duplicarver machine is driven by an electric motor and a power hydraulic cylinder.

A pantograph, which allows you to copy products to a specified scale, has a guide pin located on an axis and moving along the copier, as well as a tool spindle and an axis of rotation.

When the finger moves along the copier, the spindle on the workpiece describes the required geometric shape. The scale of the pantograph is determined by the proportions of the shoulders. Additionally, CNC can be used.

2.1 Types of copy milling machines

By type of drive:

- photocopying, hydro- and electrified, with mechanical feed;

- multi- and single-spindle units with round and rectangular tables;

- universal devices with a pantograph located vertically on a rotating arm;

- with pantograph necessary for functioning in 2 and 3 dimensions.

There are mini and full versions. Such devices can be equipped with CNC.

You can also distinguish other groups of devices that differ in workpiece clamping and level of automation:

- a desktop or manual homemade machine with mechanical profile clamping allows you to drill holes of various shapes using a template;

- automatic machine with pneumatic profile clamping - most often used for the manufacture of aluminum structures; may have CNC;

- an automatic machine with pneumatic profile clamping and a 3-spindle attachment necessary for drilling triple holes (other devices do not have this capability); may have CNC.

These can be mini or full-size machines.

2.2 Making a machine yourself

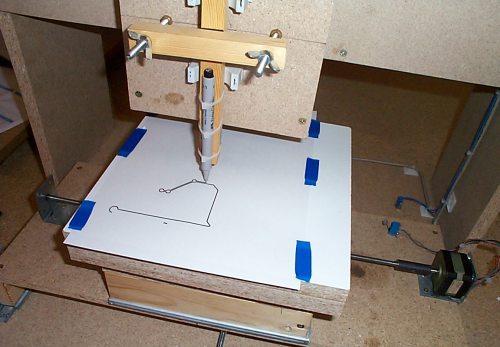

A homemade copy milling machine can be made at home with your own hands. Of course, such mini equipment will not be able to work at the same level as industrial designs, but it is quite capable of creating high-quality copies.

A homemade woodworking CNC copy milling machine can be made using a rod system, an electric motor with a clamping chuck necessary for the cutter.

The typical design of a do-it-yourself device is:

- Desktop;

- supporting frame;

- milling head.

Do-it-yourself desktop copy milling machine for wood carving with CNC must be optimized for specific purposes, which need to be achieved, for example, for threading. Understanding what parts are to be processed, you should perform calculations of size, power, and so on. Then a self-made machine will allow you to carry out the necessary tasks.

2.3 Operation of the Duplicarver copy-milling machine (video)

Both in production and at home, there is often a need to produce a part whose shape and dimensions are completely identical to the original sample. At enterprises, this problem is solved using a device such as a copy-milling machine, which makes it possible to produce copies of the original part in large batches and is characterized by high speed and the quality of the processing performed.

What is the milling process?

Copy-milling machines and any other equipment of the milling group can be found in almost any industrial enterprise. This is explained by the fact that the milling operation is one of the most common methods used to perform machining. This technology allows you to perform a wide range of roughing, semi-finishing and finishing operations with simple and shaped workpieces made of ferrous and non-ferrous metals, and to work on wood and plastic. Modern milling equipment can process parts of even the most complex shapes with high precision and productivity.

There are two main types of milling: counter (feed and rotation of the tool are in different directions) and down milling (the tool rotates in the same direction as the feed). The cutting part of the tools that perform milling is made of various materials, which makes it possible not only to successfully work on wood, but also to process (including grinding) even the hardest metals and alloys, artificial and natural stone.

Milling equipment is divided into two types: general purpose and specialized, which includes a copy-milling machine.

Capabilities of copy-milling equipment

The copying machine, which belongs to the milling group, is designed for copying and milling work with flat and three-dimensional parts. In addition, such a device can be used to engrave shaped profiles, apply inscriptions and patterns (even of high complexity) to products, and carry out light milling operations on wood and other materials.

Using tools with cutting parts made of various materials, parts made of cast iron, different types of steel and non-ferrous metals are processed on copy milling machines. Such devices for producing parts in small and large batches successfully produce blades for turbojet engines and steam turbines, propellers for ships, cutting and forging dies, impellers for hydraulic turbines, molds for pressing and casting, molds, etc.

A copy-milling machine performs technological operations that are practically inaccessible to universal equipment. The operating principle of such a machine is based on the copying method, for which a special template is used. The use of a template eliminates the human factor when processing even the most complex parts, due to which all finished products have the same shape and geometric dimensions. Conveniently, one template can be used to accurately manufacture a large batch of parts that will be completely identical to each other.

In order to copy the shape and dimensions of the template as accurately as possible, a copier (pantograph for a router) is installed on a copy-milling machine. The purpose of such a device is to accurately transfer all movements from the copy head to the cutting tool.

How does a copy milling machine work?

Copy-milling machines, as mentioned above, are used for planar (processing of profiles) and volumetric (processing of reliefs) milling. They use cutters as a working tool, which, when processing the contour or volumetric surface of a part, repeat the movements of the copier. The connection between the working element and the tracking system in manual machines is ensured by mechanical, pneumatic or hydraulic elements necessary to generate the force transmitted from the copier to the working element of the copy-milling machine.

The template on such machines is a flat contour or spatial model, a standard part or contour drawings, and the element that reads the shape and dimensions of the template is a copying finger or roller, a special probe, or a photocell. To make a template, you can use an aluminum sheet or a sheet of other metal, plastic or wood. The template and the workpiece are located on the rotating work table of the machine.

The working body of copy-milling equipment is set in motion thanks to such structural elements as a screw, spool valve, solenoid, differential or electromagnetic clutch. Relays installed in the amplification devices of copy-milling machines can be electromagnetic, hydraulic or electro-optical.

The quality of the workpiece (surface roughness, accuracy of shape and size) depends on such a parameter as the speed of movement of the tracking device. In this case, the following characteristics of the finished product can be achieved: roughness – No. 6, profile accuracy – 0.02 mm. The main elements of the executive circuit of such equipment are an electric motor and a hydraulic cylinder.

A pantograph installed on copy-milling equipment ensures copying at a given scale. The pantograph structure consists of a guide pin, its axis, a tool spindle and a separate axis of rotation. The spindle and guide pin are located on the same rail, the ratio of the arms of which determines the copying scale.

Moving along the contour of the template, the finger sets in motion the rack, which rotates freely on an axis. Accordingly, on the other side of the rack, the machine spindle makes identical movements, processing the workpiece. On do-it-yourself copy-milling machines, such a device will also not be superfluous; its presence significantly increases the functionality of the equipment.

Types of copy-milling machines

The equipment of a copy-milling machine may include various types of drives. Based on this parameter, the following are distinguished:

- equipment with a pantograph (suitable for processing parts in 2–3 dimensions);

- devices with a copier mounted on a rotary rack moving in a vertical plane;

- single- and multi-spindle machines equipped with round or rectangular rotary tables;

- machines, the feed on which is ensured by mechanical, electrical, hydraulic devices;

- photocopying equipment.

A homemade copying machine can be any of these types (including copying and grinding machines). You just need to find drawings on the Internet and select components.

According to the degree of automation and the method of fixing the workpiece, the following categories of copy-milling machines are distinguished:

- manual or desktop, on which the workpiece is fixed mechanically (on these devices you can drill holes of various shapes in accordance with the template);

- automatic equipment of a stationary type, the workpieces on which are fixed using pneumatic clamps (such machines work with aluminum);

- automatic equipment of a stationary type with pneumatic clamps, on which a three-spindle head is installed (on these copy-milling machines, triple holes are simultaneously drilled, which does not allow the production of units of the two previous types).

How does a copy milling machine work?

As noted above, on a copy-milling machine the workpiece is processed using a master device - a copier. All movements of the copier along the contour or surface of the template are transmitted thanks to a special (copying) device to the working head of the machine in which the cutter is fixed. Thus, the cutting tool exactly repeats all the movements made by the copier used to equip the router.

The movements of the elements of a copy-milling machine during the processing of a part are divided into main (rotation and movement of the spindle when cutting the tool into the workpiece material, movement along the contour of the work table and slide) and auxiliary (movement of the spindle head, slide and table in accelerated mode, as well as installation movements made by the tracer table, the copying finger, the stops and the clamp that secures the spindle head).

In copy milling machines working on aluminum, two tracking schemes can be implemented: simple action and feedback action. When implementing the direct action scheme, the working body of the machine makes movements due to the fact that it is rigidly connected to the copier. The reverse action scheme does not provide for such a connection and movements from the copier to the working element are transmitted not directly, but through a tracking system.

As mentioned above, contour and volumetric milling is performed on copy milling machines. When contour milling, the movements of the copier occur in a plane parallel or perpendicular to the axis of the tool. In the first case, the movement of the equipment working table can only be longitudinal, and the cutter and copying finger move vertically. In the second case, the table moves both longitudinally and transversely. In volumetric milling, the part is processed in stages - thanks to several movements of the table and tool performed in parallel planes.

The direct action scheme can also be implemented through a pantograph, which allows you to reduce the size of finished products in relation to the size of the template used (scale). Most often, such an additional device, which is easy to make yourself, is installed on machines used for engraving and light milling work.

Another variation of a self-made machine

How to make a copy milling machine with your own hands

Many home craftsmen would like to purchase a copy-milling machine to equip their workshop, but the cost of such equipment is quite high. Meanwhile, if you have the desire, and without spending a lot of time, effort and financial resources, you can make such equipment with your own hands.

Naturally, homemade copy-milling equipment cannot be compared with professional ones in terms of power, reliability and functionality, but such machines can also make high-quality copies, work with wood and process workpieces from other materials. Many people try to attach a copying device to an existing one, but this is impractical, since it would require redoing almost the entire machine. As practice shows, it is better to assemble your homemade copy-milling machine from scratch, selecting the appropriate components for this.

The photo below shows an example of a homemade machine with an addition in the form of a video. The creator of the machine narrates the story in English, but in principle everything is quite clear even without translation.

The easiest way to make a copy-milling device with your own hands is according to a standard design, which includes a supporting structure - a frame, a work table and a milling head. The drive to ensure rotation of the working tool is an electric motor that transmits movement through a two-stage mechanism, allowing two speeds to be obtained. The desktop of this homemade device can be adjusted in height.

Many of those who have made a copy-milling machine with their own hands note that when changing operating modes, such equipment begins to show a lot of shortcomings. The most common of these shortcomings are vibrations of the machine frame, curvature of the workpiece and its deflection, poor-quality copying, etc. To avoid such problems, it is best to make the copy-milling device highly specialized and immediately configure it to process workpieces of the same type. This is explained by the fact that it is almost impossible to take into account all the shortcomings that will arise in universal equipment when changing operating modes.

The size of a homemade copy-milling machine is of great importance, which must be selected depending on the size of the workpiece you are going to process on it. When processing large workpieces, significant vibrations arise, which only massive equipment can dampen. With such processing, serious loads are transferred to the guide axes of the machine, which must also be able to withstand it.

The first thing you need to do before making a copy-milling machine with your own hands is to decide on the tasks that you are going to solve with its help. The size of the work table, the method of securing the workpieces and template, and the direction of movement of the cutting tool will depend on this.

Depending on what parts you are going to make on your homemade copy-milling machine (as well as on the material for their manufacture), the power of the electric motor is selected. So, for engraving and other woodworking, an electric motor with a power of 150–200 W is quite suitable.

The probe and the working body of the machine are rigidly fixed to each other and installed above the work table so that the height of their location and their planes completely coincide. After installation, such a structure must move horizontally and vertically parallel to all sides of the desktop.

In the two videos below, another master talks about making a copy-milling machine with his own hands.

Designed to create various products, the shape of which practically does not differ from the given sample. The essence of using these units is that they allow you to create selected elements in large quantities, while providing greater processing speed.

Features of the use of the unit

The milling operation is one of the most common options used in material processing. A copy-milling machine for wood can perform functions such as roughing, semi-finishing or finishing processing of shaped and simple surfaces of workpieces.

This operation is characterized by its very high productivity. Thanks to this, this unit allows you to obtain parts with the correct geometric shape.

Milling methods

In order to carry out this process, you can use one of two existing methods:

- The first method is the counter milling procedure. When using this method, the feed of the element is opposite to the movement of the cutter.

- The second method is down milling, the essence of which is that the part and the cutter move in the same direction.

Currently, materials such as mineral ceramics, synthetic, and superhard are used as materials for the manufacture of cutters. However, it is worth saying that the use of such high-quality substances for the manufacture of cutters can replace the grinding procedure. But this is not very relevant for a wood milling and copying machine, since the material is initially quite soft.

It is also worth noting that there are two types of such machines:

- The first group is general purpose units.

- The second category is specialized devices.

Copy-milling equipment belongs specifically to the second category of machines.

General description of the copy-milling device

A wood milling and copying machine is used to perform copying-type work in volume as well as on a plane. In addition, the device is also used for work using three-dimensional models. To perform such operations, appropriate copiers are also used.

This unit can also be used to perform engraving operations, applying patterns, ornaments or various inscriptions. The greatest advantage of a wood milling and copying machine is that, with its rather simple structure, it is capable of performing a large number of different complex operations.

The essence of the work

It should be noted that the ability of the device to work with various materials depends on the alloy from which the cutter is made. Operations can be carried out not only on wood, but also on steel, cast iron, and non-ferrous metals. To do this, it is necessary to use carbide as the material for the cutter, as well as provide a high number of revolutions per minute. These types of units can be used both for large-scale production and for the production of small batches.

For example, such devices can be used to produce things such as ship propellers, turbojet engines, steam turbines, various shapes, molds, and wood blanks.

It is worth noting that models of a CNC copy-milling machine for wood are produced. The purpose of this type of device is to perform the milling operation of curved parts. To perform such a task, these machines use a pattern copying method. The use of this method helps eliminate the human factor. This is very important, since a person is not able to create two perfectly identical things, unlike a machine. As a result of the mechanization of the process, that is, the use of machine tools, it became possible to conveyor production of various parts and elements with a curved shape and absolutely identical dimensions.

DIY machine

Today it is possible to purchase such a device on the market. However, the possibility of creating a homemade wood milling and copying machine cannot be ruled out.

Since there are quite a few designs of this equipment, its typical, most common form will be presented.

The components of such a unit are as follows:

- working surface;

- supporting frame or bed;

- milling head.

It is important that the working surface of the equipment has the ability to be adjusted in height, and that the milling head is equipped with an electric drive. In addition, a two-stage mechanism must be connected to it, the task of which is to provide two different speed levels of the milling head.

A fairly common disadvantage of homemade devices is that they are not able to create an exact copy of the product. The reasons for this are most often trembling, vibration, as well as a change in the direction of the cutter. It will not be possible to avoid all flaws, and therefore, in order to minimize their presence, experts recommend creating a narrowly focused equipment model, rather than trying to make it universal.

When making a copy-milling machine for wood with your own hands, you need to create a drawing and design all the parts in such a way that in the future it will be convenient to work with workpieces of the selected size. For example, there are two types of work - milling long workpieces or engraving. These two operations require that the method of fastening the workpiece, as well as the work surface, be completely different.

This is not the only reason why you need to think things through in advance. The second thing that anyone who creates a machine on their own will have to face is the choice of an electric motor. Depending on the density of the material with which you will need to work, it is necessary to select the power of this product. If we talk about working with wood, then most often a motor with a power of 150 to 220 W is enough.

Another feature that must be observed is the most durable fastening of the copy probe and the device that holds the cutter. These two small details are very important, since the accuracy with which the machine can reproduce the model from the sample will depend on this.

Milling and copying machine for wood "Duplicarver"

The purpose of this equipment is to perform operations such as wood carving, copying sculptures and flat relief objects. The main advantage of this particular device is that it has the best price-quality ratio. And its characteristics are suitable for both professional work and beginners.

These devices can perform wood carving in two ways:

- Volumetric or sculptural carving. This operation is the main one for this machine. It allows you to create exact copies of models from wood materials.

- Flat relief carving. This type of work includes carving door panels, panels, or any other workpieces that have a shallow image depth.

Milling and turning copying machine for wood

The purpose of this type of machine is processing wooden products, turning profiles and decorative blanks. A distinctive feature of this type of equipment is the presence of two cutters at once. One of them is mounted on a steady rest and is intended for processing round wood blanks. This cutter is capable of removing up to 10 mm of material in one pass of the part. Settings for this element are configured on a special device.

The second cutter is mounted in the copy carriage, and its main purpose is to turn blanks according to the sample. In order to ensure comfortable work with long elements, the unit has a steady rest that can be attached to the guide rod. It is used as the main support to prevent the long workpiece from bending. It is also possible to install a part such as a faceplate. This allows you to process parts with a large number of edges.

To carry out a full range of woodworking with a hand router or on a milling table, you need not only conventional devices, such as cutters of various sizes, but also additional devices that will help perform more complex work. The tool must have the ability to create a workpiece of the shape that is needed according to the master’s idea.

Some such devices are included with the device, but if they are not available or if you plan to make it yourself, then additional parts can be made manually. As a rule, they are quite simple to manufacture. In addition to various stops, you can also make a copier for the router with your own hands and install the structure on the frame base.

You can build a milling and copying machine yourself using a hand router. The device can be of different designs, but it has one task - to convey as clearly as possible the movements of the working head along the profile holder to the device that cuts out the material.

It is not always possible to buy a ready-made machine with a copier, so it is often made independently from improvised means. It is recommended to assemble it first; it is difficult to adapt the copier to a serial device; this requires a thorough reworking of it.

Characteristics of the works themselves

Milling cutters equipped with copiers are used for volumetric manipulation and processing of planes. They cope with work that uses three-dimensional forms, engraving of various shapes, drawings, patterns, and inscriptions. They can also do simple milling functions. Such designs are distinguished by their simplicity, but at the same time they are capable of producing surprisingly complex patterns and shapes.

Not only wood, but also cast iron, steel, and non-ferrous metals are suitable for working with such a machine; for this purpose, high-speed tools made of hard alloys are used. On an industrial scale, similar units, but of course larger ones, are used to produce engine blades for aircraft, ship propellers, hydraulic turbine ridges, various models, metal blanks, stampings, cast and pressed parts.

A self-made copier is used when drilling key holes for bolts. They can make frames, grooves, channels of any size in plastic and metal profiles.

But the most interesting thing is that it can be used to mill curved parts, copying them according to a template. The latter allow you to make an exact copy and eliminate the human factor in such complex work. The parts have an exact, perfectly uniform shape.

Identical parts are made using a template; all subsequent parts can be made according to the sample of the first one. For the clearest and most accurate copying, the router is equipped with a copier; such a device is also called a pantograph.

Return to contents

Operating principle and device

Briefly, the principle of operation of the copier is this: using a probe, the contours of the original of the copied object or pattern are traced. The probe is connected to the working plane, at the other end of which the milling cutter is attached, so all movements of the probe are repeated by the milling cutter head.

The machines have a guide system, an electric motor and a chuck for clamping the cutter or router. A simple design is described here.

The standard design consists of:

- working surface and supporting frame;

- milling working head;

- copy probe.

To make a copier with your own hands for a hand router, you will need:

- frame made of wood or metal, if based on a lathe, then such a machine;

- boards and slats, thick plywood, wooden blocks;

- fasteners (bolts, nuts, screws);

- milling cutter;

- a set of wrenches, a hacksaw for cutting the required size of wooden parts;

- metal pipe, guides;

- drills for wood and metal;

- belt drive and electric motor (if it is not manual, but automatic).

The working plane is adjusted in height, the head is equipped with an electric drive motor and a two-stage gear mechanism, which creates two speeds for the router shaft. This is for more complex designs.

If you have a lathe and a manual milling machine, you can build a very good copying machine that will work on large workpieces. This requires a minimum of details.

Making a copier with your own hands is not so difficult.

A hand router is used as the main tool. It is installed on a base made of thick plywood (12 mm), its parameters are 500/200 mm.

A hole is made on it for the sole of the router and mounting bolts. A frame and supports are also made from bars, this serves as additional stabilization and fixation of the tool. Two smaller bars are fixed to the plane of the plywood at the edges. The router is mounted between these two bars with pins (bolts or nails) through holes in its base and made in the plywood.

The platform with its far end slides along the pipe along the structure, that is, it is attached to a block that runs along it. You can take a metal pipe of 1 and ¾ inches. It is fixed between two cubic bars; it seems to hang over the machine with the carriage and cutter. In addition, it is folding. These bars are attached with self-tapping screws to the frame. The pipe is aligned as evenly as possible along the axis of the machine; it coincides with its axis. It is also fitted with two wooden cubes with holes corresponding to it to ensure sliding. It is to them that such a carriage is attached.

Another bar is also attached to the front side of the machine frame, but this is horizontal, and the profile template is fixed on it. It is fixed to two wooden posts vertically on both sides. Its upper part runs exactly along the axis of the machine. When the copier is no longer needed, it is removed and the router and carriage are folded back. A vertical crossbar is attached to the bottom in the middle; it slides along the recesses of the template, copying the relief. This is the copier itself, it is attached with self-tapping screws, in which case it can be removed and replaced or the height adjusted. A template is attached to the block along the facade with self-tapping screws. The platform moves with your hands.

This machine is designed for simple three-dimensional parts such as chair legs, candlesticks, where there are no twisted elements.

In the modern world, there is often a need to create a copy of something or reproduce and repeat something. For this purpose, many enterprises widely use copy-milling machines, which are designed to create products whose shape most closely matches the given original sample. They make it possible to produce parts in large quantities, while ensuring high speed of processing and manufacturing of each element.

Features of the milling procedure

Milling is one of the common machining methods. Using milling, roughing, finishing and semi-finishing of shaped and simple surfaces of workpieces made of steel, non-ferrous metal, cast iron and plastics is carried out. Milling is characterized by a high level of productivity, which allows the final result to obtain products of the correct geometric shape.

Milling can be carried out in two ways: the procedure of up milling (against the feed), when the feed is opposite to the direction of rotation of the cutter, and down milling (along the feed), when the directions of rotation of the cutter and feed coincide. Using cutters that are equipped with modern cutting materials (mineral ceramics, synthetic super-hard), you can process materials that are hardened to high hardness, thereby replacing the grinding procedure.

Milling machines are designed for milling the surfaces of levers, strips, housings, covers and brackets of simple configurations, complex configurations of contours (such as templates, cams), and surfaces of body parts. Milling machines are divided into two main categories: general-purpose machines and specialized machines. The first group includes longitudinal milling, cantilever, non-cantilever and continuous milling machines. The second category includes thread-milling, gear-milling, slot-milling, key-milling and copy-milling machines.

Purpose of a copy milling machine

Copy-milling machines are usually used to perform copying work in volume and on a plane, as well as in volume using three-dimensional models and corresponding copiers, for engraving various shaped profiles, patterns, ornaments and inscriptions, as well as for light milling work. The indisputable advantage of such units is that they are capable of producing incredibly complex patterns with their own simple design.

The machine can perform various milling operations on steel, cast iron and non-ferrous metals using high-speed and carbide tools in large- and small-scale production. On such machines, propellers of ships, blades of turbojet engines and steam turbines, impellers of hydraulic turbines, cutting and forging dies, press and casting molds, various cams, dies, molds, metal models and blanks are produced.

Such equipment is also used for drilling holes for handles, locks, latches, metal hinges, as well as making frames for mirrors and channels of any size on plastic and aluminum profiles, as in the video about copy-milling machines. On universal machines, the processing procedure for such products is almost impossible.

A copy-milling machine is intended for milling curved parts using a copying technique according to a template from which the shape of the future product is copied. The use of templates makes it possible to eliminate the influence of the human factor during such a complex operation, and all finished parts, as a result, have the same shape.

To make several completely identical products, you can not only use a single template, but also make all subsequent parts based on the first one. However, for the most accurate repetition, it is recommended to supplement the machine with a copying device called a pantograph. Its design can be different, but the function is the same in all cases - to more accurately transmit the movement of the copying head along the profile to the cutting device.

Design of copy milling machine

The copy-milling machine is designed for processing profiles (planar milling) or reliefs (volumetric milling) of products using a carbide cutting tool - a milling cutter. The cutter reproduces on the product the contour or surface of the setting device - the copier. The driving device of a manual copy-milling machine has a pneumatic, mechanical or hydraulic connection with a tracking system, which is responsible for directing the cutting tool, on the one hand acting on the amplifying device, and on the other influencing the executive body.

A flat template, a spatial model, a reference part, a contour drawing can act as a copier, and a probe, a copy roller or finger, or a photocell can serve as a copy device. Samples for copying can be made of metal, plastic or wood. The workpiece and the copier are mounted on a rotating table.

The executive body can be a spool, a screw, a solenoid, an electromagnetic clutch, or a differential. In the amplification devices of copy-milling machines, electromagnetic, hydraulic or electro-optical relays are used. The surface roughness of the workpiece and the accuracy of the profile depend on the speed of movement of the tracking device: roughness No. 6 and a profile accuracy of 0.02 millimeters are achieved. The actuator circuit is driven by a power hydraulic cylinder and an electric motor.

Copying at a specified scale is carried out using a special device called a pantograph. If you are interested in how to make a copy-milling machine yourself at home, then you can supplement it with this device. The pantograph has a structural guide pin, which is located on an axis and moves along the copier, a rotation axis and a tool spindle. When moving along the finger pattern on the workpiece, the spindle describes a geometrically similar figure. And the copying scale is determined by the proportions of the pantograph arms.

Types of copy milling machines

Based on the type of drive, the following main types of copy-milling machines are distinguished: with a pantograph, which is designed to work in 2 and 3 dimensions; universal devices with a pantograph, which is located on a rotating arm in a vertical plane; single- and multi-spindle units with rectangular and round tables; with mechanical feed, electrically and hydraulically, as well as photocopying.

There are several types of similar milling and copying machines, which differ in the level of automation and clamping of the workpiece being processed:

- Manual or desktop copy-milling machine with mechanical profile clamping. With its help, you can drill holes of various shapes according to a template, however, for triple holes you will need a three-spindle attachment on a machine or drill.

- Automatic (stationary) milling and copying machine with pneumatic profile clamping. Such machines also do not allow triple holes to be made for installing handles and, as a rule, are used for the production of aluminum structures.

- Automatic (stationary) milling and copying machine with pneumatic profile clamping and a 3-spindle attachment for drilling triple holes.

Operating principle of a copy milling machine

Processing of products on a copy-milling machine is carried out using a master device (copier), the action of which causes, through the copy device, a corresponding movement relative to the workpiece of a special cutting tool. Through the copying device, the copier acts on the actuators, while the workpiece and the cutter recreate in relative motion the surface that is specified on the copier.

The main movements are rotation of the spindle, movement of the table and slide along the contour, and movement of the spindle head when cutting. Auxiliary movements - acceleration of movement of the slide, spindle head and table, installation movements on the table of the tracer table, stops, copying finger and clamping of the spindle head.

Aluminum copy-milling machines are capable of operating according to 2 tracking schemes: action with feedback and simple action. The copy probe and the cutter in the simple-action scheme are rigidly connected to each other, and the movement of the probe along the copier is transmitted to the cutter. The deflection of the trace probe in the feedback circuit causes a mismatch in the position of the trace probe relative to the cutter.

The result of such a mismatch is sent to a special tracking system, which issues a signal to the actuator to adjust the tool path. In this case, there is no rigid connection between the cutter and the copier, and the copier does not perceive the cutting force, but only transmits the corresponding signal to the executive bodies.

There are two types of copy milling - volumetric and contour. When contour copying, the copier curve can be placed in a plane that is parallel or perpendicular to the axis of the cutter. In the first case, the table with a copier and the workpiece moves in the longitudinal direction; control of the change in the curve is accomplished due to the vertical movement of the cut-in and the carbon finger. In the second case, the table with the copier and the workpiece moves in the transverse and longitudinal directions according to the shape of the curved line of the copier.

The complex spatial surface of the workpiece during volumetric copying is processed with a cutter sequentially, through several parallel table strokes, that is, contour copying is performed with each working stroke. At the end of the pass, the cutter is shifted relative to the workpiece perpendicular to the line by the amount of the transverse feed, then the next working stroke occurs.

There are also direct-action copy-milling machines, in which the milling probe transmits movement through the pantograph. Such machines are mainly used for light engraving and milling work. When using a pantograph, in addition to copying, it is possible to reduce the scale of workpieces in relation to the copier. The movement of the copy probe along the copier, which is installed on the machine table, is transmitted to the spindle, which, when processing the workpiece, describes a contour similar geometrically to the copier.

Do-it-yourself copy-milling machine

Currently, the market offers milling and copying machines of various designs and levels of complexity. However, it is not always possible to buy one, and the price of a copy-milling machine is quite high. Therefore, we often face the question of how to make a copy-milling machine at home.

Of course, homemade machines cannot fully compete with industrial models, but they are still functional and allow you to make high-quality copies. I would like to immediately make a reservation that it will be very difficult to adapt a copying device to an industrial milling device, and this concerns, first of all, a radical redesign of the entire device. Therefore, the easiest way to assemble a homemade copy-milling machine is practically “from scratch” using a rod system and an electric motor with a clamping chuck for the cutter.

There can be many designs of copy-milling machines. The typical design of the apparatus is as follows: the machine structurally consists of a work table, a supporting frame and a milling head. The working surface can be adjusted in height, the milling head is equipped with an electric drive motor and a two-stage transmission mechanism that provides two speeds of the milling shaft.

Many homeowners complain that when copying a product, the resulting part has many flaws and inconsistencies that appeared when changing the direction of the cutter, vibration and trembling of the supporting structure. Adding to the trouble is the sagging and curvature of the workpiece, which is associated with an increase in internal stress due to the removal of wood. It is impossible to avoid all the shortcomings when making a homemade copy-milling machine. It is simply recommended to make the copying machine narrow-profile, and not universal.

A homemade copy-milling machine should be optimized for the production of specific products that you need. For example, to effectively manufacture a wooden part of a gun and a propeller screw, different technical solutions are required; they cannot be combined in one machine, and side effects that are difficult to correct may occur. Thus, it is more practical to assemble machines for specific tasks. This approach can save you many costs and difficulties.

An important factor is the size of the machine. The larger the product you plan to process, the more massive the design should be. It is necessary that the vibrations transmitted from the cutter drive are absorbed by the weight of the machine's supporting structure. Loads must be supported by guide axes, which must also have a safety margin and not bend. The optimal parameters when designing a copy-milling machine with your own hands are selected experimentally, this ensures smooth operation of the cutter.

When designing a copy-milling machine, determine the type of parts you will produce. To perform engraving work and to mill long products, a different work table and a method for securing workpieces with a template on it are required. Freedom of movement in different planes of the cutting tool depends on the type of work table.

The power of the electric motor, which rotates the cutter and is installed on a homemade copy-milling machine, depends on the parts being manufactured and their material. For engraving and milling of wooden products, a 150-200 watt DC electric motor is sufficient.

To ensure an accurate copying procedure, you need to rigidly connect the copying probe and the device to each other, securing the cutting tool in it. In this case, their height and planes above the desktop must coincide completely. The created rigid structure should be installed above the desktop in such a way that it can move in the vertical and horizontal planes along the axes that are conventionally created by the sides of the desktop.