How does video LED work? Device of LED light sources

Issues of reducing electricity consumption are resolved not only at the state level. This problem is also relevant for ordinary consumers. In this regard, not only powerful, but also economical light sources are beginning to be widely introduced in apartments, offices and other institutions. Among them, more and more widespread LED bulbs. The design and principle of operation of the LED lamp allows it to be used with a standard socket and connected to a 220 V electrical network. In order to do this right choice, you need to know the main advantages and features of modern light sources.

Large screens are divided into two main groups: indoors and outdoors. In addition, they are built with a greater temperature difference. Interior screens have a much shorter viewing distance than exterior screens because the diode pitch is only used.

It consists of a motherboard with control electronics, a main and backup power supply, and a solid metal housing. Its front is planted with clusters.

Operating principle of LED lamps

The operation of LED lamps uses physical processes that are much more complex than those used in conventional incandescent lamps with a metal filament. The essence of the phenomenon is the appearance luminous flux at the point of contact between two substances made of dissimilar materials, after passing through them electricity.

It combines the basic blocks into one mechanically stable block. You can choose a rigid design suitable for permanent installations such as house fronts or a removable design that allows you to change the shape of your screen as needed.

A classic metal network cable is used.

It processes image information from multiple inputs and then sends it to the screen control unit. We have to deal with this! Maximum current, which the pins of this chip can pass through is about 40 mA. We see that we have more than doubled this flow.

The main paradox is that each of the materials used is not a conductor of electric current. They belong to the category of semiconductors and are capable of passing current only in one direction, provided they are connected to each other. In one of them, negative charges must necessarily predominate - electrons, and in the other - ions with a positive charge.

Most of the chip consists of transistors. They are now very small and also susceptible to damage. If a circuit passes through a current, it always converts electrical energy into thermal energy. There is not enough room for a small transistor to cool quickly enough. This may cause some parts of it to evaporate, which is definitely not the case and you will find a better pin.

Prepare for a shocking revelation - even without a resistor! If the heating does not exceed a certain limit, this procedure is relatively safe. A fluorescent diode, or light-emitting diode, is a semiconductor electronic component that emits a narrow spectrum of light when it passes through an electrical current in a conductive direction. The illuminating effect results from the bright pairing of red electrons and is a form of electroluminescence. The color of the emitted light depends on chemical composition semiconductor material used.

In addition to the movement of electric current, other processes occur in semiconductors. When transitioning from one state to another, thermal energy is released. Through experiments, it was possible to find combinations of substances in which, along with the release of energy, light radiation appeared. In electronics, all devices that pass current in only one direction began to be called, and those that have the ability to emit light began to be called LEDs.

The cheapest infrared diodes are produced, followed by the cheapest red ones. Green is about 20% more expensive than red. Blue, according to the manufacturer, is even more expensive than red, but Lately their price fell sharply. We also know their use in large format displays used for advertising purposes. With long service life and shock resistance, they are also used in automobiles, even as a replacement for the end brake or directional light. In-house solutions for lamp replacement are so expensive.

Laser diodes found wide application and in data storage. The most serious disadvantages include: The shortened wavelength of the emitted light increases the voltage at which the current in the transmitted direction begins to increase. The main monocrystals of the diode are covered with spherical canopies of epoxy resin or acrylic polyester.

At the very beginning, the emission of photons from semiconductor compounds covered only a narrow part of the spectrum. They could only emit red, yellow or green light, with very low luminous intensity. Therefore, for a long time, LEDs were used only as indicator lamps. To date, materials have been obtained whose compounds have made it possible to significantly expand the range of light radiation and cover almost the entire spectrum. However, some wavelength always predominates in the glow. Therefore, LED lamps are divided into sources of cold light - blue and warm light - mainly red or yellow.

This leads to their use in displays. Contacts can be either surface-mounted, flexible or flexible. Parallel connections are usually a problem. Differences in the manufacturing process may cause wiring failure. Less reliable methods for determining polarity are.

So we can say that the energy consumed is practically a function of the current. This method is commonly used. Others include a set of diodes different colors, located in groups connected to a common anode or cathode. Here we can achieve a wider range of different colors without changing the polarity of the power supply.

Device of LED light sources

The appearance of LED lamps is practically no different from traditional light sources with a metal filament. They are equipped with threads, which allows them to be used with conventional cartridges and without making changes to the electrical equipment of the premises. However, LED lamps differ significantly in their complex internal structure.

The most common ones are red, yellow or green. Most of them only shine in one color, but are also available in multi-colored colors. We can save space on printed circuit board. This can be especially useful when developing prototypes or changing intended wiring.

Characteristic stress values in the permeable direction

This depends on the manufacturing technology, type of semiconductors used, temperature and current. They produce more light per watt of energy than light bulbs, which is useful in battery-powered or energy-saving applications. They can emit light of the desired color without the use of complex color filters. Their housing can be designed in such a way as to concentrate light on a specific location. Light heat and fluorescent substances should mainly concentrate the light on the external optical system. In devices where we need a "dimming" function, it does not change color as the power supply decreases, unlike light bulbs, which produce more yellow light as the power increases. They are impact resistant. They are ideal for use on devices where the device is turned on and off frequently, unlike light bulbs that can burn easily when turned on and off frequently. They have higher acquisition costs than traditional light sources. Other costs also arise because one diode is relatively weak and therefore we need more. However, when you take the overall costs, they far outweigh bulbs and halogen light sources. In cases of more high temperatures Sufficient cooling must be ensured.

Light sources for machine reading systems

Their performance is highly dependent on ambient temperature. . Machine scanning systems often require clear and uniform lighting to better perform the required activity.

They include a contact base, a housing that acts as a radiator, a power and control board, a board with LEDs and a transparent cap. When planning to use LED lamps in a 220 V network, you should remember that they will not be able to work with such current and voltage. In order to prevent the luminaires from burning out, power and control boards are installed in their housings, reducing the voltage and rectifying the current.

This allows the controlled part to be illuminated by a uniform light source from precisely defined angles. They are easily replenished with small, inexpensive lenses and diffusers to help achieve high light density and light control. They can be easily used to create a flash and are already powerful enough to achieve well-lit images even with very short light pulse durations. However, it may happen that the diode burns out if we exceed its throughput voltage, which is approximately 0.5 to 3 volts depending on the color used.

The design of such a board has a serious impact on the life of the lamp. In some models, only a resistor is installed in front, and in some cases, unscrupulous manufacturers do without it. As a result, the lamps produce a very bright glow, but burn out very quickly due to the lack of stabilizing devices. Therefore, high-quality lamps are certainly equipped with stabilizers, for example, ballast transformers. The most common control circuits use anti-aliasing filters, which include a capacitor and a resistor. The most expensive models use microcircuits in the control and power units.

In addition, it is almost impossible to transmit only white light, only with the help of a phosphor could light like white be achieved. Interestingly, each color needs a different voltage to emit it, which is listed here in a table. If we need to change the color, it is enough to reduce or increase the brightness of the diodes, which we achieve by changing the voltage.

Cross section of a diode with details on the radiation unit. This efficient light source works on the principle of semiconductors, which converts electrical current directly into light. They can be applied to virtually all new and existing light sources, as long as proper installation and use are followed.

Each individual LED emits a fairly weak light. Therefore, to achieve the desired lighting effect, the required number of elements is grouped. For this purpose, a board made of dielectric material with applied conductive tracks is used. Approximately the same boards are used in other electronic devices.

They also provide a longer service life and therefore greater savings. They can emit light of the desired color without the use of color filters. The most common colors are white, yellow, red, orange, green and blue. The best-selling color of light is, of course, white, and this is characterized by what is known as color temperature, simplified by hue and color rendering index, which is the ability to accurately display the entire spectrum of colors. So you can choose between "warm, neutral or cool" white light.

These controllers are equipped with digital controls with different color effects that can be manually changed, programmed, etc. Light luminaires can be made that have a non-fixed but user-changing shade of white, such as the current situation and mood. The light may not always be the same, but dynamic or even multi-colored.

The LED board is also a step-down transformer. For this purpose, all elements are connected in series to a common circuit, and the mains voltage is evenly distributed between them. The only significant drawback of this circuit is that the entire chain breaks if at least one LED burns out.

The angle can be adjusted by external optics as needed. As a result, the radiation angle is usually in the range from 10 to 120 degrees and can be not only round, but also elliptical or other as desired and intended. They are much more resistant to shock and vibration than conventional light sources.

They are ideal for use in applications that require frequent switching on and off, as conventional lamps can be damaged by frequent switching on and off. They are very small and can be easily mounted on a PCB. They have been the most common since the very beginning of their production. Most often they are known with round sleeve diameters of 3 and 5 mm. However, these cases also have limited opportunities to exhaust heat.

The entire lamp is protected from moisture, dust and other negative influences by a transparent cap. Some properties of the cap allow you to enhance the overall glow. The fact is that its inner side is covered with a layer of phosphor, which begins to glow under the influence of quantum energy. Therefore, the outside surface of the cap looks matte. The phosphor has a wider emission spectrum, several times higher than that of LEDs. As a result, the radiation becomes comparable to natural sunlight. Without such a coating, LEDs are irritating to the eyes, causing fatigue and pain.

They are the cornerstone of most of our products, especially LED ledgers. We can divide them by power: low power, average power and high power. They contain tens to hundreds of individual chips, most often in series-parallel wiring placed on a thermally conductive substrate. They achieve such high luminous flux, but have significant heat removal requirements.

This arrangement, together with the double-sided phosphor, provides a high beam angle. Existing technologies also provide longer service life and therefore greater savings. For general lighting, the most commonly used color is the so-called dynamic white, the shade of which can be changed from cold to warm tones.

Best to study useful qualities, design and principle of operation of LED lamps on circuit diagrams at voltage electrical network 220 volt. Most often, such lamps are used in industrial and street lighting, and in domestic conditions, traditional light sources are replaced by LED bulbs operating at low voltage, mainly 12 volts. However, the power of the lamp and its light output are not directly related to each other. This factor should be taken into account when choosing LED lamps.

In LED lamps designed for 220 volts, there is no transformer in the circuit. In this regard, additional savings arise in the operation of such lamps. This feature distinguishes them from LED lamps with other powers. Therefore, the choice of lamps is not based on power, but on the degree of illumination created by them.

Advantages of LED lamps

Currently great importance is given to the economical and durable operation of lighting devices. Therefore, lamps that create bright lighting with the release of a minimal amount of heat and low energy consumption come to the fore. They have low sensitivity to changes in current and voltage and can withstand a large number of switching on and off.

LED lamps fully possess all these qualities. They have several varieties, differing in design and technical specifications, which allows you to choose the most suitable option. All lamps differ in the presence or absence of lamps, the degree of environmental safety, and the need to use rectifiers and other additional devices.

An LED is a type of diode, an electronic device with one-way conductivity of electric current. A diode, or as it is also called a rectifier diode, having its unique properties change electrical resistance depending on the polarity of the voltage applied to it, it is used for rectification alternating current. The design of the rectifier diode can be built both on the basis of radio-electronic tubes and on the basis of semiconductor crystals.

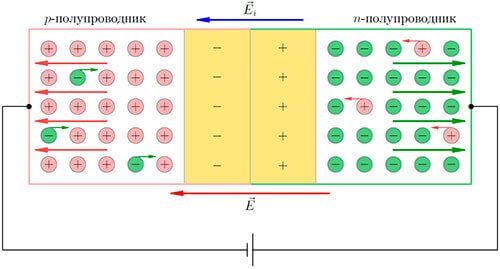

Unlike a rectifier diode, an LED is made only on the basis of semiconductor crystals. The operating principle of both electronic devices is based on the injection (diffusion) of electrons and holes in the area p-n transition, that is, the area of contact of two semiconductors with different types conductivity. By injection we mean the transfer of excess electrons from the region n-type in the area p-type, as well as the transition of excess holes from the region p-type in the area n-type, where there is a lack of them. As a result of injection, uncompensated layers of electrons and holes are formed in both regions, near the transition boundary. On the side n-transition layer of holes, and on the side p-transition layer of electrons. These layers form a so-called blocking layer, the internal electric field of which prevents further injection (Figure 1).

Figure 1. Barrier layer p-n transition

A certain balance emerges. When a negative voltage is applied to a region of the crystal with conductivity n-type and positive voltage to the region of the crystal with conductivity p-type, under the influence of an external electric field directed against the blocking field, the path is opened for the main carriers through p-n transition. The barrier layer becomes thinner and its resistance decreases. There is a massive movement of free electrons from n-regions in p-area and holes from p-regions in n-region. An electric current arises in the circuit (Figure 2).

Figure 2: Forward switching

If reverse voltage is applied, the barrier layer becomes thicker and the electrical resistance increases significantly. Electric current when supplied reverse voltage practically absent (Figure 3).

Figure 3. Turning on in reverse direction

It must be remembered that the permissible value of reverse voltage for LEDs, at which its breakdown does not occur, is significantly lower than for rectifier diodes. Often this value is equal to the maximum forward voltage value. Therefore, turning on the LED in electrical circuit alternating current, we should not forget about the amplitude value of the voltage. For a sinusoidal voltage with a frequency of 50 Hz, its amplitude value is 1.41 times greater than the effective value. Such inclusions are rarely used, since the purpose of the LED is still to “glow” and not “straighten”. Usually the LED is turned on at a constant voltage.

Video 1. Semiconductors

When free electrons move through p-n transition electrons and holes emit photons due to their transition from one energy level to another. Not all semiconductor materials efficiently emit light when injected. For example, diodes made of silicon, germanium, and silicon carbide practically do not emit light. And diodes made of gallium arsenide or zinc sulfide have the best emitting abilities.

The emitted light is not coherent and lies in a narrow spectrum. In this regard, each LED has its own spectrum of waves, with its own length and frequency, which may or may not be visible to the human eye. As an example of the use of LEDs with an invisible emission spectrum, we can cite the LEDs used in remote control remote control any modern radio-electronic equipment. In order to see the radiation, take a remote control and any cell phone with a photo-video camera. Put your phone in video shooting mode, point the camera lens at the front edge of the remote control and press any of the buttons on the remote control. At the same time, you will see the LED glow on the phone screen.

The emission spectrum depends on the chemical composition of the semiconductor crystal. Each radiation spectrum has its own color. Therefore, LEDs emitting light in the spectrum visible to the human eye are perceived as multi-colored, red, green, blue.

The glow of a solid-state diode was first discovered by British experimenter Henry Round. In 1907, conducting his research papers he accidentally noticed that a glow appeared around the point contact of a working diode detector. However, he did not draw a conclusion about the practical application of this phenomenon.

A few years later, in 1922, Oleg Vladimirovich Losev, during his night radio watches, just like Henry Round, accidentally began to observe the emerging glow of a crystal detector. To obtain a stable glow from the crystal, he applied voltage from a galvanic battery to the point contact of the diode detector and thereby passed an electric current through it. This was the first attempt to find practical use LED operation.

In 1951, research work began in the USA on the development of “semiconductor light bulbs”, the action of which was based on the “Losev effect”. In 1961, the technology for manufacturing an infrared LED was discovered and patented, the authors of which were Robert Bayard and Gary Pittman. A year later, in 1962, Nick Holonyak, working at General Electric, manufactured the world's first red LED operating in the light range and subsequently finding its first practical application. It had low energy efficiency, consumed relatively high current, but at the same time had a dim glow. Nevertheless, the technology turned out to be promising and was further developed.

The next step in the development of LED technology was the invention of the yellow LED. A former student of Nick Holonyak, George Craford, in 1972, together with the invention of the yellow LED, increased the brightness of red and red-orange LEDs by 10 times. Almost simultaneously with these inventions, in the early 70s, green LEDs were produced. They found their application in calculators, wristwatches, electronic devices, light signs and road traffic lights. A significant increase in luminous flux, up to 1 lumen (Lm), of red, yellow and green LEDs was achieved only by 1990.

In 1993, a Japanese engineer working for Nichia, Shuji Nakamura, was able to produce the first high-brightness LED that emitted blue light. This invention was a revolution in the development of LED technology, as LEDs were produced in three primary colors, red, green and blue. From this moment on, it was possible to obtain a glow of any color, including white.

In 1996, the first white LEDs appeared. They consisted of two LEDs - blue and ultraviolet with a phosphor coating.

By 2011, LED designs were built white glow, which provided light output up to 210 Lm/W. How did scientists and engineers achieve such success? To do this, let’s look at currently known methods for producing white LEDs.

It is known that all colors and shades are made up of three primary colors - red, green, blue. White light not an exception. There are four options for producing radiation from white LEDs (Figure 4).

Figure 4. Obtaining LEDs emitting white light

The first option is to use three separate LEDs in the design. p-n transitions emitting red, green and blue light. With this option for everyone p-n The transition requires its own power supply. By adjusting the voltage on each p-n transition, they achieve the creation of a white glow with its own shade (color temperature).

The second option - with this option, the LED design uses one p-n transition of a blue glow, coated with a yellow or yellow-green phosphor. This option is used most often, since the LED requires one power source to operate. However color characteristics This LED is inferior to the characteristics of LEDs obtained by other methods.

Third option - one is also used here p-n transition of a blue glow, but covered with layers of phosphors of two colors - red and green. LED designs produced using this method provide better color characteristics.

The fourth option - the design of the LED in this option is based on an ultraviolet LED coated with three layers of phosphors red, green and blue. The designs of such LEDs are the least economical, since the conversion of short-wave ultraviolet rays into long-wave visible rays, in all three layers of the phosphor, is accompanied by energy losses.

Light output value over bright LEDs white color of 210 Lm/W has so far been achieved only in laboratory conditions. The maximum luminous output of bright LEDs available for general use does not exceed 120 Lm/W. Such LEDs are very expensive and are rarely used. The bulk of LEDs have a light output of 60 - 95 Lm/W.

The luminous output of an LED, as well as any other light source operating under the influence of electrical energy, depends on the magnitude of the current passing through it. The higher the current, the greater the light output. But just like any other light source, most of the energy in it turns into heat. Heating of LEDs is accompanied by a decrease in their light output. In this regard, manufacturers are forced to use massive metal cases to cool the crystal and dissipate the generated heat into environment. Such measures make it possible to slightly increase the efficiency of its use.

If we compare the energy efficiency of various light sources, it turns out that LEDs have a coefficient useful action 40 - 45% are the most economical. For example, incandescent paws have an efficiency of 2 - 5%, - 15 - 25%, - 24 - 30%.

The operating mode of the LED, when the crystal is at a temperature close to room temperature, undoubtedly has a beneficial effect on its service life. Under these operating modes, the LED can operate for up to 50,000 hours without losing light output. If the goal is to increase the light output by increasing the current, then this will naturally have a detrimental effect on its service life. First of all, towards the end of its service life, the light output drops significantly. The drop occurs smoothly and reaches 70% of the initial value. Secondly, the likelihood of its complete failure increases.

This fact suggests that when choosing luminaires and lamps when developing lighting projects, it is necessary to evaluate each time which one is more profitable from an economic point of view.